- Home

- Companies

- Yokota Manufacturing Co., Ltd.

- Products

- Model UPSA - Defoaming Pumps

Model UPSA -Defoaming Pumps

It is often the case that gas bubbles are generated in the processing of liquids such as liquid foods, beverages and chemicals, and the bubbles cause the following difficulties: Measurement of liquid quantity becomes inaccurate, and flow rate control becomes difficult. Troublesome and costly removal of overflowing bubbles. Bubbles cause difficulty in sending liquid to the next process. Bubbles overflow during packaging, causing deterioration in packaging efficiency. These problems have been commonly dealt with by giving time for the bubbles to settle down. However, this creates new problems due to the amount of time required for bubbles to settle down, causing a loss in processing time, and the necessity of installing a large tank for stabilization of liquid, which increases processing costs.

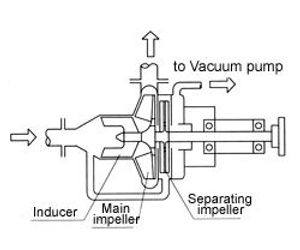

- When pumping liquid containing gas bubbles flows into the inducer, liquid and gas are initially separated by rotation of the inducer. The mist-like gas-liquid mixture accumulates in the central area of the casing.

- The gas-liquid mixture is transferred through the main impeller to the separating impeller. The remaining liquid in the mixture is further separated and the gas is drawn out by the vacuum pump.

- The liquid separated by the separating impeller returns to the intake of the inducer by centrifugal force.

- Minute gas bubbles remaining in the liquid are confined to the central area of the casing by the pressure difference generated by the main impeller and transferred to the separating impeller, by which defoaming efficiency is further enhanced.

- Food industry: Defoaming of foods and dairy products in processes such as boiling, extraction, mixing, and fermentation

- Beverage industry: Defoaming of milk, beverages, wine, beer, other, in processes such as boiling, extraction, mixing, and fermentation

- Chemical industry: Defoaming of gas-containing liquid, foam latex, foam starch liquid, normal paraffin fermenter liquid, other

- Packaging: Defoaming of liquid foods, beverages, pharmaceuticals, detergents, cosmetics, paints, other, before packaging/bottling (improvement of packaging efficiency by prevention of overflow)

- Machine industry: Defoaming of lubricants, hydraulic oil, cutting oil, other

- Others: Defoaming processes in treatment systems for pulp, waste water, sewage, other

- Also highly suitable for applications such as extraction from sealed tanks (vacuum tanks), and suction and transfer of liquid containing large amount of gas bubbles.