Hydro-Probe - Moisture Sensor for Bins, Chutes and Conveyor Belts

The Hydro-Probe was the first moisture sensor to use the digital microwave moisture measurement technique. It has integral signal processing which provides a linear output (both digital and analogue) and it can easily be connected to any control system. Typical applications include sand, cement, concrete, asphalt and aggregates. For organic materials the Hydro-Probe XT is recommended.

Designed for use in processing plants which use bins (silos), chutes and conveyor or feed belts, the sensor is positioned into the flow of material. Measurements are taken 25 times per second as the material passes over or around the sensor face, meaning that the sensor can rapidly detect changes in moisture levels. Real time adjustments to the moisture content of the material can then be made during processing if required. This ensures that the manufacturer can continually produce a consistent, quality product and reduce costs by limiting the amount of wasted or spoilt materials.

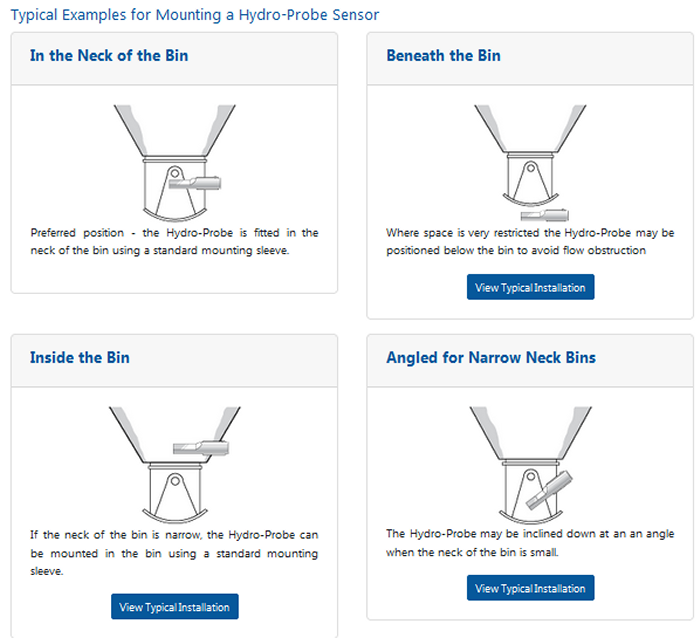

The sensor can be installed in a variety of locations where there is a flow of material. Some typical examples can be found on our installations page. A range of accessories are available including extension mounting sleeves and clamp rings to assist with fitting.

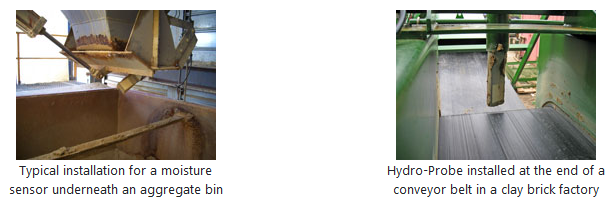

Hydro-Probe Digital Moisture SensorThe Hydro-Probe is a digital moisture sensor that is designed to measure moisture continuously in the flow of material across the ceramic sensor faceplate. Measuring at 25 times per second the sensor detects rapid changes in moisture, providing a linear digital or analogue output.

Digital technology provides precise, linear moisture measurement.

Advanced Digital Signal ProcessingThe sensor response may be adjusted remotely using the Hydro-Com software to minimise the effects of noise of the measured signal. Advanced Digital Signal Processing provides a clear signal with a rapid response.

Fully Temperature Compensated MeasurementThe sensor internally adjusts for mechanical changes due to temperature fluctuations

Easy to Interfacewo analogue outputs and digital RS485 communications and configurable digital inputs / output make the sensor simple to integrate into a control system.

Measuring in the MixMeasuring at 25 times per second the sensor continuously detects changes in the moisture of the materials throughout processing.

Temperature MeasurementTemperature output is available to provide a readout of material temperature.

Sensor ConfigurationThe Hydro-Probe can be remotely configured using Hydro-Com diagnostic software. All readings and sensor parameters are available including the type of output and filtering characteristics.

A unique feature is the `angling` of the sensor face plate to the flow of the material. This ensures consistent flow characteristics over the sensor face and prevents build up or "clogging" of the material at the sensor. The sensor should be positioned at an angle of 60 degrees to the flow but this may be easily adjusted to suit the flow characteristics of any material.

Batch AveragingThe `averaging` mode continuously provides the `average` reading of moisture from the start of reading to any time selected - normally the closing of the hopper door. Averaging, bin empty alarms and signal processing performed internally by sensor.

Accuracy of MeasurementAll measurements may, if required, be calibrated to an accuracy of +/- 0.2%. If used to reach a target the accuracy can be better than 0.1%

CalibrationThe sensor may be internally calibrated using the Hydro-Com software, or the linear output may be calibrated within the control system or by use of the Hydronix Hydro-View calibration unit.

Simple Power RequirementsThe Hydro-Probe may be powered from a 15-30V dc supply. Multiple sensors may be driven from a single power source.

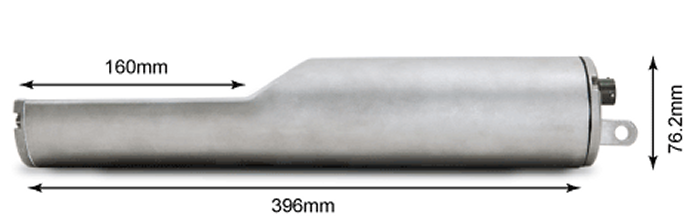

The Hydro-Probe is a rugged, digital, microwave sensor designed to measure moisture in flowing materials. Typical applications include moisture measurement in abrasive materials such as sand, aggregates and concrete.

- Body: Stainless Steel

- Faceplate: Ceramic

The sensor must be placed in the flow of material.

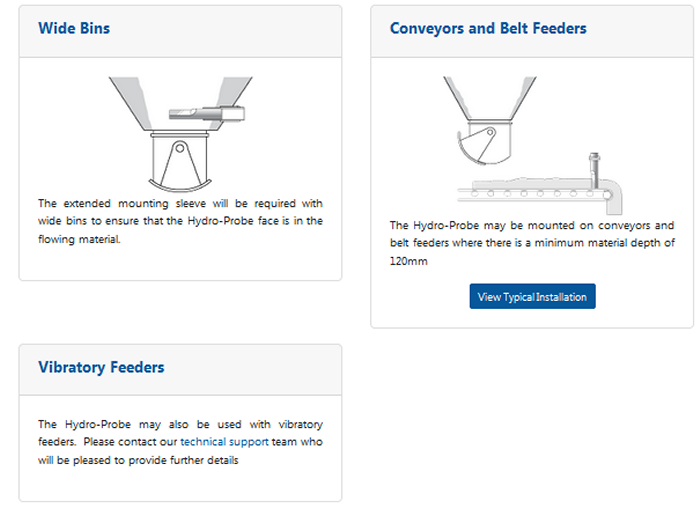

Bins and Silos:- Install in the neck of a bin or underneath the gate. Standard and Extension Mounting Sleeves are available to suit different bin widths.

Conveyors:- Secure in the flow of material

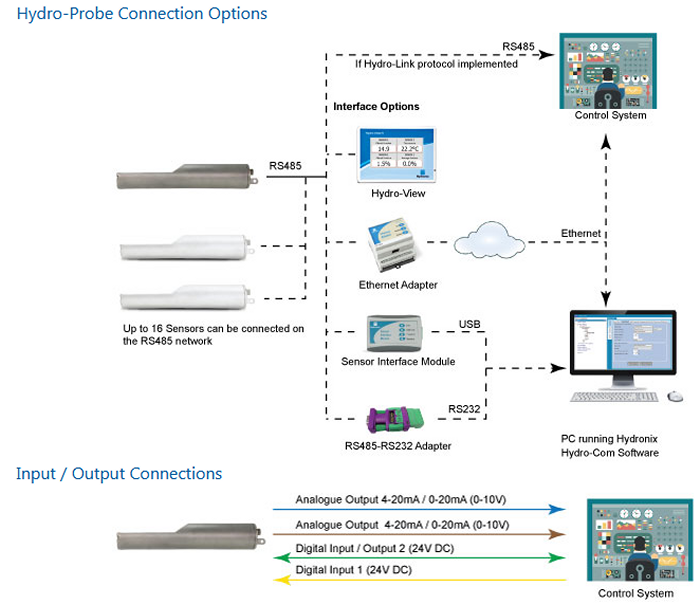

2 Configurable 0-20mA or 4-20mA current loop source available for moisture and temperature. May also be converted to 0-10V DC.

Digital Inputs/Output2 configurable digital signals are provided for batch average start/stop or for moisture / temperature multiplexing purposes.

Digital (Serial) CommunicationsOpto-isolated RS485 2-wire port. Uses Hydro-Com communications protocol for read/write access to sensor parameters and values. Ethernet and USB interfaces are also available.

The sensor will measure up to saturation of material.

Material PenetrationApproximately 75-100mm dependent on material.

Operating Temperature0-60 degrees C. The sensor will not measure in ice.

Refresh RateOutputs are updated 25 times per second.

ConnectionsThe sensor is fitted with a 10-way MIL-SPEC connector. A 4, 10 or 25 metre, 6 twisted pair cable pre-assembled for connection to a waterproof junction box is available.

Power Supply+15Vdc to +30Vdc. 4W

The Hydro-Probe microwave moisture sensor has a built-in choice of connection options using either analogue or serial. The RS485 serial interface allows up to 16 sensors to connect directly to a control system via a serial communications link. There are 2 analogue outputs which can be configured to 4-20mA, 0-20mA (0-10V), 1 configurable digital input and 1 configurable digital input / output. These different options provide the plant manager with the flexibility to select the most suitable method of connecting to their control system.

There are various options for interfacing between the sensor and the control system using a Hydronix approved Ethernet, USB or RS232/RS485 adapter. Alternatively, the Hydro-View moisture display can be used to provide real time on-line process measurements including both moisture and temperature. In it`s simplest configuration the analogue output from the Hydro-Probe can be connected to a Scaleable Current Loop Display to display the current moisture. These different options provide the plant manager with the flexibility to select the most suitable method of connection for their own control system.

Cabling

Hydronix supplies various cable lengths incorporating the required 10 way MIL-SPEC connector. This enables the sensor signal to be sent to a Control System or PC for configuration and calibration.

Recommended field cabling:

- Six pairs twisted (12 cores total) screened (shielded) cable with 22 AWG, 0.35mm2 conductors

- Screen (shield): Braid with 65% minimum coverage plus aluminium/polyester foil

- Recommended cable types: Belden 8306, Alpha 6373

- Maximum cable run: 100m, separate to any heavy equipment power cables

The Hydro-Probe microwave moisture sensor has been designed for a variety of mounting options. The most typical installation is in or underneath a bin (silo) or above a conveyor or belt feed. These different options provide the installer with flexibility in determining the most suitable location for the sensor to be installed.

The Hydro-Probe should be mounted in the flow of material which must pass across the ceramic faceplate of the sensor. To ensure that the material flow is not obstructed and to prevent build up on the sensor face, the moisture probe should be installed at an angle of approximately 60 degrees to the flow of material. For installations where the silo is wide an extension mounting sleeve can be used.

The examples below show diagrams of typical mounting for the Hydro-Probe in a bin (silo) and a conveyor or belt feeder.

Full details regarding installation and calibration can be found in the User Guide. This is available for download in many different languages. Details for the extension mounting sleeve and other Hydro-Probe accessories can be found on the sensor acessories page.