Hydro-Probe Orbiter - Moisture Sensor for Mixers and Conveyors

The Hydro-Probe Orbiter is a digital microwave sensor designed specifically to measure moisture and temperature in fast flowing abrasive materials. With a choice of mounting options for static pan, rotating pan and planetary mixers the sensing head moves easily through the mix providing accurate moisture measurement of the material in real time.

Originally supplied to the concrete industry, the Hydro-Probe Orbiter can also be mounted as a static sensor underneath a bin or above a belt conveyor and is therefore easily adaptable for use in other industries such as sand, aggregates, cereal, animal feed and fish meal.

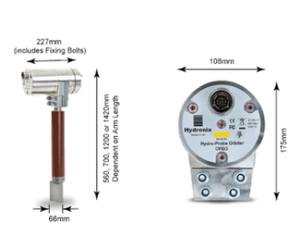

The Hydro-Probe Orbiter consists of 2 parts - the head unit which houses the electronics and connections and the sensing arm with a hard wearing ceramic. Both the sensing arm and the head unit can be easily changed eliminating the need to replace the entire sensor. To extend the life of the Hydro-Probe Orbiter, the sensing arm should always be fitted with an arm guard and protection rings.

The Hydro-Probe Orbiter microwave moisture sensor consists of two parts, the head unit which contains the electronics, and the sensing arm, which takes moisture readings. The arm is easily replaceable and cuts through the mix providing a rapid measurement of both moisture and temperature of the material. To extend the wear life of the arm, Hydronix recommends that in all cases the arm is protected from excessive wear by use of a arm guard and protection rings.

Unlike other sensors which are positioned so that the material flows over the sensor face, the Hydro-Probe Orbiter is designed to move rapidly through the mix. This provides a very fast response to changes in moisture.

Temperature MeasurementA temperature sensor in the ceramic at the end of the sensing arm provides a fast response reading, enabling temperature correction for adjusting water addition, or for controlling steam heating equipment.

Improved SamplingThe Hydro-Probe Orbiter is installed approximately 50mm above the floor of the mixer. This provides a faster response to added moisture in the mix.

Easy to InstallThe Orbiter is easy to install and there is no requirement to cut a hole in the mixer floor.

Easy to clean by hosing/brushing to remove build up of materials. Regular checking for wear is required.

No Build UpUnlike floor mounted sensors, the Orbiter is not affected by uneven mixer floors.

Replaceable Sensor ArmThe main sensor body and electronics are positioned out of the mix, and should not have to be changed. The sensing arm is available as a replacement item, so when worn or damaged, the sensing arm may be changed with only minimal disruption to production.

Different Arm LengthsVarious arm lengths are available depending on the mixer type and fixing position

Rotating ConnectorFor applications using a static pan mixer a rotating connector is available which provides a reliable connection to the Orbiter while allowing it to rotate.

The Hydro-Probe Orbiter is a rugged, hard wearing, digital moisture sensor that has been designed for use in mixers. It can be static mounted for rotating pan mixers or conveyor belt applications, or can be used as a rotating sensor, fitted to the mixer arm in static pan mixers.

- Body: Stainless Steel

- Sensing Face: Ceramic

The sensor is designed to be clamped to a vertical 25mm square mild steel bar (supplied by the customer).

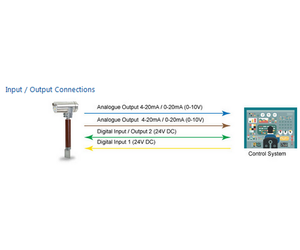

Analogue Outputs2 Configurable 0-20mA or 4-20mA current loop source available for moisture and temperature. May also be converted to 0-10V DC.

Digital Inputs/Output2 configurable digital signals are provided for batch average start/stop or for moisture / temperature multiplexing purposes.

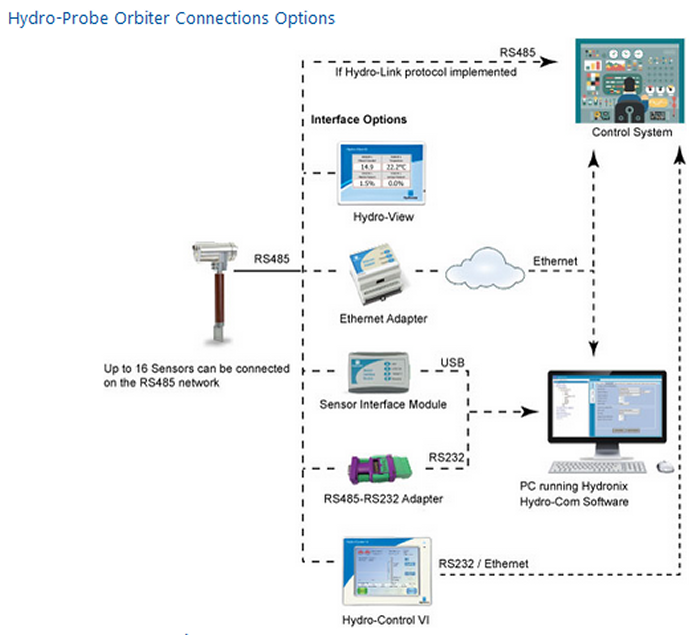

Digital (Serial) CommunicationsOpto-isolated RS485 2-wire port. Uses Hydro-Com communications protocol for read/write access to sensor parameters and values. Ethernet and USB interfaces are also available.

The sensor will measure up to saturation of material.

Material PenetrationApproximately 75-100mm dependent on material.

Operating TemperatureThe standard Hydro-Probe Orbiter operates to a temperature of 0-60 Degrees C. The high temperature arm will work in materials with a temperature of up to 100 Degrees C as long as the electronics can be kept to a temperature of 60 Degrees. The sensor will not measure in ice.

Refresh RateOutputs are updated 25 times per second.

ConnectionsThe sensor is fitted with a 10-way MIL-SPEC connector. A 4, 10 or 25 metre, 6 twisted pair cable pre-assembled for connection to a waterproof junction box is available.

Power Supply+15Vdc to +30Vdc. 4W

The Hydro-Probe Orbiter moisture sensor can be connected to a control system in three ways: analogue, digital or via the Hydro-Control water control unit. The RS485 serial interface allows up to 16 sensors to connect directly to a control system via a serial communications link. There are 2 analogue outputs which can be configured to 4-20mA, 0-20mA (0-10V), 1 configurable digital input and 1 configurable digital input / output. These different options provide the plant manager with the flexibility to select the most suitable method of connecting to their control system.

There are various options for interfacing between the sensor and the control system using a Hydronix approved Ethernet, USB or RS232/RS485 adapter. Alternatively, the Hydro-View moisture display can be used to provide real time on-line process measurements including both moisture and temperature. In it`s simplest configuration the analogue output from the Hydro-Probe Orbiter can be connected to a Scaleable Current Loop Display to display the current moisture.

Cabling

Hydronix supplies various cable lengths incorporating the required 10 way MIL-SPEC connector. This enables the sensor signal to be sent to a Control System or PC for configuration and calibration.

Recommended field cabling:

- Six pairs twisted (12 cores total) screened (shielded) cable with 22 AWG, 0.35mm2 conductors

- Screen (shield): Braid with 65% minimum coverage plus aluminium/polyester foil

- Recommended cable types: Belden 8306, Alpha 6373

- Maximum cable run: 100m, separate to any heavy equipment power cables

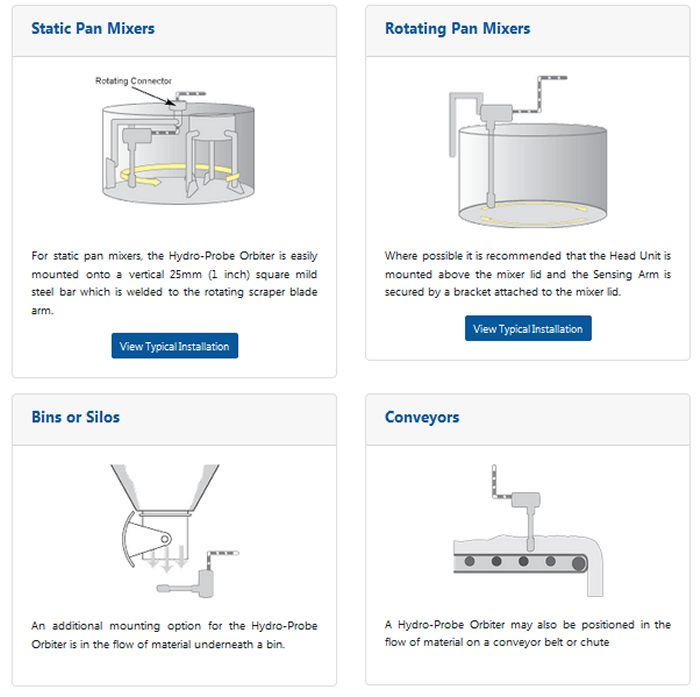

For installations in static pan mixers, the head unit of the Hydro-Probe Orbiter is mounted onto the mixer scraper blade arm which rotates through the mix. For this type of mounting Hydronix recommends that our rotating connector is used. Installations in rotating pan mixers require the sensor to be fitted to a securing bar inside the mixer. Other installation options include positioning the sensor above a conveyor belt or underneath a bin or silo. Moisture measurements are then taken as the material flows around the sensor head.

Sensor arms are available from Hydronix in several lengths to accommodate different mixers and applications. These include, 560mm, 700mm, 1200mm and 1420mm. The length refers to the overall length of the sensor when the Sensing Arm is connected to the Head Unit. For most applications including mixers it is recommended that the Sensing Arm is mounted 50mm from the floor.

The examples below show diagrams of typical mounting for the moisture sensor. Full details regarding installation and calibration can be found in the User Guide

The Hydro-Probe Orbiter may be easily mounted in static pan mixers such as Turbo or Planetary mixers when used with a Rotating Connector. It is fitted to the top of the mixer and provides a simple way of connecting the plant wiring outside of the mixer to the sensor wiring within the mixer to allow all relevant signals from the sensor to be accessed.

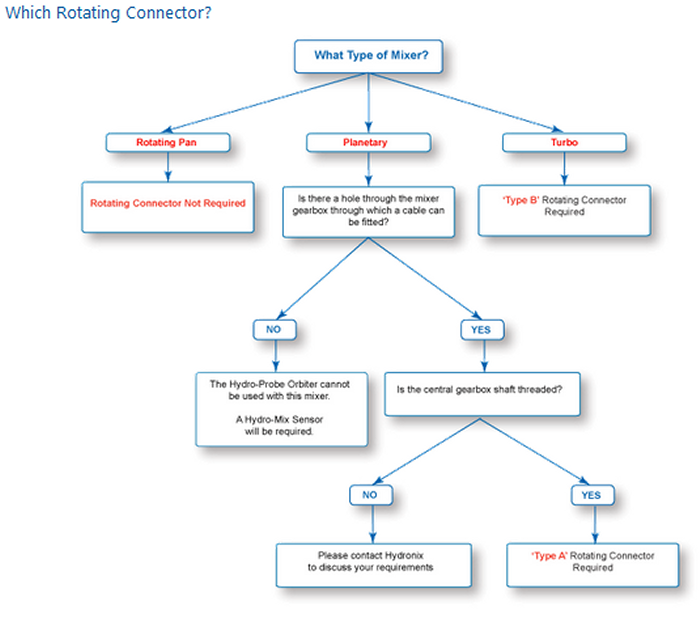

There are 2 different options of Rotating Connector:

- Type A - Designed for a threaded central shaft in the middle of the top of the mixer gearbox that the cable will pass through.

- Type B - Designed for mounting on the top of the mixer lid to allow the cables to pass through.

The chart below will assist in choosing the correct Rotating Connector for your mixer type.