- Home

- Companies

- Moving Floor AB

- Products

- Moving Floor Pig Equipment

Moving Floor Pig Equipment

Do you know that generally 7 times more water is used for cleaning for the pigs than what the pigs actually drink themselves? Moving Floor Pig equipment is cleaned 10-15 times/day without using any water at all. This continous cleaning helps reducing the ammonia emissions by 95%. The solid floor is soft but has a resistant surface that spares the pigs’ knees and hooves. Healthy animals grow better and need less antibiotics. With Moving Floor pig equipment you can also build the barns to a lower cost than conventional barns with slatted floors.

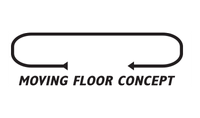

- The floor gets dirty by manure and urine

- In programmed intervals the floor rotates and the manure and urine is scraped off in the front

Simplify construction

Moving Floor Pig can simplify the construction and reduce the building cost

Increased growth rate

Tests show a potential increase in growth rate for pigs, increased hygiene helps lowering infection pressure

Saving labor

All cleaning is done automatically, even bedding/rooting materials can be distributed automatically

Low energy consumption

Average energy consumption is

No water

No water is used for daily cleaning

Pay back

On average 2 years calculating only operational costs, no animal health aspects such as increased growth rate is included

95% less ammonia emissions

Moving Floor Pig barns have a 95% lowered ammonia level in comparison to conventional pig barns

Low maintenance need

No training is needed for performing service, average cost for spare parts is 50 RMB/year

Moving Floor has received financing from EU programme EIP to create the concept of automatic cleaning for pigs. The project consist of the design and manufacturing of the units as well as putting up a barn to test the equipment under veterinary supervision.

Moving Floor has also been granted an initial funding for combining Moving Floor with drum composting technology in order to strive for a closed manure handling system with little gas emissions.

Measures

- Weaning and finishing pen;

- Length: 5600 mm

- Width: 2600 mm

- Height: 1000 mm

- Surface: 11 sqm

- Weigth: 800 kg

Material

- Conveyor: Ultra resistant conveyor specially developed for pigs

- Frame: Wooden frame covered with stainless steel

- Sides: Plastic

- Front gate: Hot dip galvanized steel

Installation

- Pig equipment for new as well as renovated barns

- The unit has adjustable legs

- Compressed air: 8 Bars (compressor not included)

- Control: PLC (transformer not included)

Drive

- Electricity: 24 V DC

- Drive: Brake bell

- Compressed air: 8 Bars

- Consumption compressed air: 2 liters/movement