Westech Industrial Ltd.

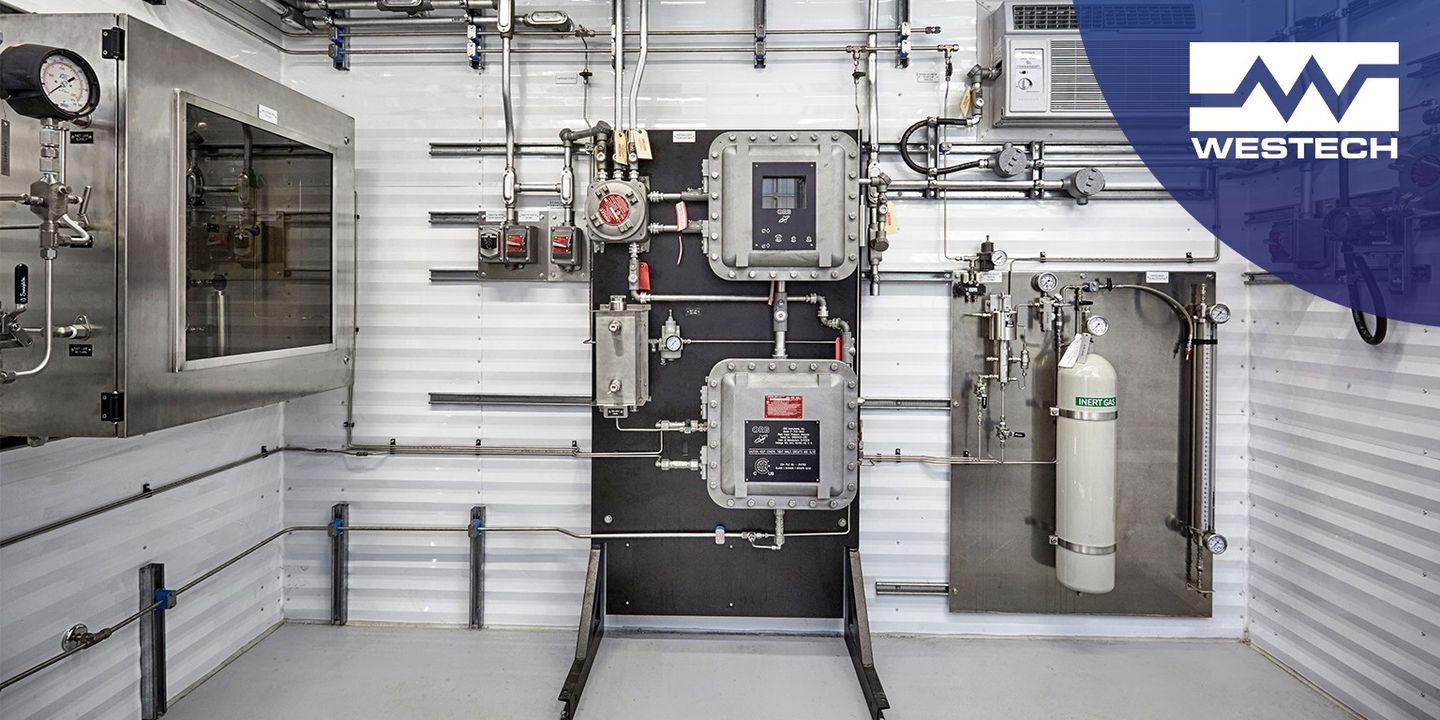

SICK - Model MCS200HW -Multi-Component Analyzer System for Continuous Monitoring

The MCS200HW is a multi-component analyzer system for continuous monitoring of up to 10 IR measurement components in flue gases of industrial combustion plants. The MCS200HW is hot/wet extractive: All parts which touch media, from the gas sampling probe to the cell, are heated above the dew point and therefore protected from corrosion. An integrated oxygen sensor also measures oxygen. As an option, a TOC measurement can be supplemented via an integrated GMS811 FIDORi. Internal reference point monitoring allows for a quick check of the measured values with test gases. The web display and the task assistant integrated in the software makes operation very easy.

Most popular related searches

analysis system

gas sampling probe

analysis system monitoring

TOC measurement

sampling probe

oxygen sensor

gas sampling

flue gas

oxygen monitoring

sample gas probe

- Measurement of up to 10 IR components plus O2 and TOC

- Hot/wet extractive measurement technology

- Wear-free gas distribution through ejector pumps

- Reference point monitoring with internal calibration cells

- Certified digital Modbus® interface

- Web server for platform-independent device control

- Use of dry test gases for HCl and NH3

- Reliable measurement results, even for water-soluble gas components

- Only one analyzer necessary for simultaneous monitoring of up to 12 gas components

- Measurement components can be put together flexibly and extended at any time

- Convenient, task-oriented operation

- Remote access without additional software

- High availability due to certified internal third-party monitoring (QAL3) without test gases

- Low service costs thanks to minimal maintenance requirements

- Complete data transmission through only one interface possible

Available: ONT, QC, Maritimes