- Home

- Companies

- Monroe Environmental Corporation

- Products

- Monroe - Multi-Stage Air Scrubbing ...

Monroe - Multi-Stage Air Scrubbing Systems

Monroe Environmental can provide complete multi-stage air scrubbing systems for a wide variety of applications. High temperature and volatile chemical processes often require a more complex, customized air scrubbing solution than what a simple packed tower scrubber or venturi particulate scrubber can provide.

In many cases, several technologies must be integrated together to provide adequate removal and treatment efficiencies. Monroe’s experience includes the engineering and fabrication of customized Multi-Stage Scrubbers utilizing the following equipment:

- Packed Bed Scrubbers

- Venturi Particulate Scrubbers

- Wastewater Clarifiers

- Oil Recovery Units

- Carbon Adsorbers

- Quench Towers

- Cyclonic separators

- Heat exchangers and temperature controls

- Sub-cooling systems

- Dry injection fabric filters (DIFF)

- Fiberglass filters

- WESP and submicron particulate filters

- Specialty ducting systems

Customized Scrubbing Solution

Monroe has the experience and knowledge to evaluate your process and recommend a customized scrubbing solution for your specific application. We have successfully treated contaminated air streams from nearly every high temperature emissions application across a variety of industries and processes.

Most Cost-Efficient and Effective Fume Scrubbing Solutions

Monroe Environmental engineers analyze each application individually to determine the most cost-efficient, effective solution. Monroe has an extensive arsenal of standard wet air scrubbing equipment offered in a variety of standard and special construction materials backed up by over forty years of experience in solving such complex problems.

Dual-Train Wet Scrubbing System

Flame Laminating Exhaust Treatment Multiple Venturi and Caustic Scrubbing

- Train (1) — 5,500 CFM

- Train (2) — 7,600 CFM

Air Composition

- HCl

- HCN

- CO2

- CO

- Particulate

Solutions for High Temperature Scrubbing Processes

Monroe Environmental provides gas scrubbing systems for combustion processes including incineration, oxidation, flame laminating, glass coating, and other high temperature operations exhausting dryers, ovens, furnaces, gassifiers, reactors, and kilns.

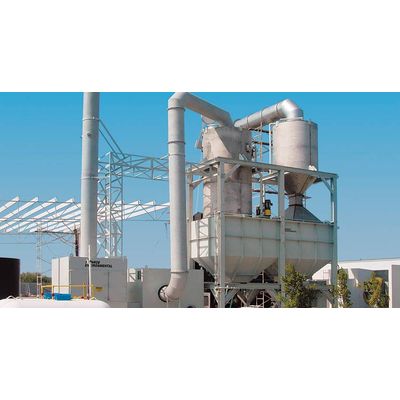

Monroe Scrubbing System at Industrial Waste Facility

20,000 CFM — Incinerator Exhaust Scrubbing, Stainless and Mild Steel Construction

- Ceramic-lined steel ducting – Corrosion and temperature control

- Rapid water quench – 2,000°F to less than 200°F

- Adjustable Venturi Scrubber – Particulate removal

- Horizontal Clarifier tank – Solids settling

- Packed Tower Scrubber – HCl scrubbing

- Carbon/filter housing – Final filtration and discharge polishing

Scrubbing Systems for Chemical and Compound Reclamation

Contaminants formed in these processes are frequently highly corrosive, hazardous, and/or difficult to remove. Removal often requires contaminant incineration at temperatures exceeding 1,500°F. Through proper quenching and gas conditioning techniques, Monroe can provide reclamation of costly chemicals and compounds contained within the off-gasses.

Monroe Scrubbing System at Grease Production Plant 15,000 CFM — Mild Coated Steel Construction

- Dual-Throat Venturi Scrubber to remove particulate

- Drag conveyor to remove settled material

- Oil Skimmer (right) to recover condensed grease

- Packed Tower Scrubber to remove hydrocarbon vapors

Multiple Packed Bed Scrubbing Systems

For some applications, multiple Packed Bed Scrubbers in series provide the best contaminant removal solution. This type of scrubbing system is common when there is a high pollutant loading or when removal efficiencies greater than 99.9% are required. Having multiple scrubbing stages also allows the use of different scrubbing solutions within a single scrubbing system for removal of different contaminates within the same air/gas stream.

Multi-Tower Scrubber — Toxic Gas Incineration

1,253 SCFM — Stainless and mild, coated steel

- Quench stack: 2,000°F to less than 190°F

- (3) Phase Packed Bed Scrubber with sub-cooling loop: metals, condensables, HCl, SO2, and NOX removal

- High energy Venturi Scrubber: submicron particulate/aerosol removal

- Electric gas reheater

- Dry injection fabric filter baghouse with PAC for final acid gas removal

- Carbon Adsorber housing: final filter/polishing

- Solid waste incineration

- Chemical gas incineration

- Kiln exhaust scrubbing

- RTO exhaust scrubbing

- Oven/furnace exhaust scrubbing

- Flame laminating

- Dryer exhaust scrubbing

- Glass coating

- Grease & chemical production

- Textile manufacturing

- And many others