- Home

- Companies

- Fluid Equipment Development Company ...

- Products

- FEDCO - Model MSS Series - Multistage ...

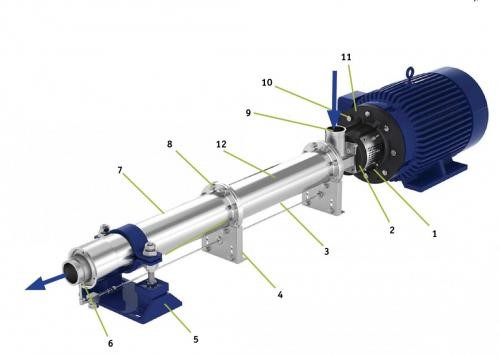

FEDCO - Model MSS Series -Multistage Centrifugal High Pressure Feed Pumps

MSS pumps are multistage centrifugal feed pumps specifically designed for brackish and seawater reverse osmosis service, representing the most reliable high-pressure feed pump available today. Loaded with unique features such as the patented Water Bearing™ thrust bearing, product-lubricated shaft bearings, and maintenance-free design, the MSS ensures years of trouble-free operation. The MSS also features one of the longest warranties in the industry – a full 18 months of coverage from the date of product installation.

Multistage centrifugal high-pressure feed pumps that provide a new level of reliability and efficiency in seawater reverse osmosis pumps

- 7.5 – 295 m3/h (33 – 1300 gpm)

- Pressures to 83 bar (1200 psi)

- Duplex SS Pressure Containment

- Impeller and Diffuser are 316 SS – electropolished & passivated

- Shaft seal operates at low pressure

- Flexible disc coupling

- Bearing drain line (low pressure)

- 316 SS shell support bracket

- Precision leveling foot

- Grooved end pipe joints

- Duplex SS 2205 housing

- Flanged construction for easy internal inspection

- Inlet rotatable in 90° increments

- Easy shaft alignment

- Integrated motor adapter (anodized aluminum alloy)

- 316L SS stages – passivated & electropolished – proven in hundreds of SWRO applications

- WATER BEARING™

All MSS pumps can be equipped with a high inlet pressure option to allow inlet pressure to 70 bar. This unique design features:

- Use of low-cost, standard mechanical seals, operating at low pressure (typically 1-2 bars)

- Total protection of the motor from pump thrust loads - a major problem with high inlet pressure operation.

- Pump shaft kept in tension -no potential for shaft buckling

- Handles total axial thrust -no load on motor bearings

- Never needs lubrication

- Bearing cooled by feed water -no ambient temperature limit

- 316L SS stages, passivated and electropolished