- Home

- Companies

- Research International, Inc.

- Products

- Oracle - Non-Contacting Gas Detector

Oracle - Non-Contacting Gas Detector

The Oracle is a non-contacting gas identifier with part-per-million sensitivity that requires no consumables and which is operable over a wide temperature range. It is essentially a long baseline infrared spectrometer that identifies gases by comparing their infrared (IR) signatures with a built-in library of target gas signatures. A beam of infrared light from a remote source ( it may be located up to 50 meters away) is intercepted and spectrally analyzed by a base station spectrometer. The unique vibrational spectra associated with the target gases or atmospheric reaction products enable high reliability identification. Figure 1 shows the Oracle installed in an ASAP V. However, the Oracle may also be used as a stand-alone system.

Figure 1: Oracle system principle of operation.

Advantages of this method are that it is fast (1 second to alarm), sensitive, specific, reliable, and requires no consumables. In contrast to electrochemical detectors, the Oracle has a much lower chance of false readings due to cross-sensitivity, and there are no electrolytes to dry or leak out. In contrast to IMS gas detectors, Oracle’s spectral signatures are generally more unique than IMS signatures and there is a smaller chance of misidentifying the target gas. In addition, there is negligible effect of humidity and there are no scrubber packs to periodically replace.

Perhaps most importantly, the Oracle is not a point sensor - it will detect gases that pass anywhere between its remote light source and the main spectrometer receiver. This means that the probability of detecting a toxic gas plume within the local area is significantly improved since the targeted gas does not have to contact either the remote light source or the instrument. This can also reduce the number of detection devices required for a particular application since area coverage per detector is greatly improved.

The device is provided with Ethernet connectivity. This means that each unit can be queried from anywhere in the world if the user knows the unit’s IP address.

- Fast (1 second)

- Line, not point sensor

- Sensitive

- Detection library of over 40 gases

- Requires no consumables

- Transit systems and subways

- Critical infrastructure protection

- Sports stadiums and arenas

- Homeland security

At the present time, the built-in library comprises 40 chemical warfare agents (CWAs) and toxic industrial chemicals (TICs) as shown in the table below.

Toxic Industrial Chemicals

- Ammonia

- Chloroethane

- Diborane

- Ethylene Oxide

- Formaldehyde

- Hydrogen Bromide

- Hydrogen Chloride

- Hydrogen Cyanide

- Hydrogen Sulfide

- Phosgene

- Vinyl Chloride

- Propylene

- Carbonyl Sulfide

- Acrylonitrile

- And many more

Industrial Materials

- Aqueous ammonia cleaner

- IsoClean

- Stainless cleaner

- Propane

- Butane

- Natural gas

- Carbon Dioxide

- DMMP

- DIMP

- Methyl Salicylate

- FM-200(Heptafluoropropane)

- Sulfur Hexafluoride

- Alcohols and solvents

- Diesel and Gasoline exhaust

The detected infrared signal is divided into 16 separate segments within the 8 to 12 micron and the 3 to 5 micron wavelength ranges. The signal strengths in these wavebands are compared with the library target gas spectral data and background air data using a proprietary mathematical tool that provides a ‘closeness’ of fit to background and target gas signatures. When the fit meets internally preset criteria that the profile is a statistically significant deviation from background and matches a particular gas, details of the measurement are sent to remote monitoring software via Ethernet connection.

Recalibration of the instrument is an infrequent requirement. The system can be set up to perform periodic self-tests. During the self-test a polymer flag is moved into the beam and the spectral signature of that material is compared to internal library data. If the signature matches, recalibration is not required. Self-test results are also reported via the Ethernet connection.

Path-average Concentration

Since the width of a detected plume will typically be unknown, calculated concentrations are presented in “ppm-meters.” That is, if a gas is detected to be present at a concentration of 10 ppm-meters, this could correspond to a range of actual concentrations. For example, if the detected cloud was known to be 10 meters wide, then the actual average plume concentration would be 1 ppm. If the system installation is designed so that the user knows the gas plume’s width, then actual average concentrations can be provided. In the table below, true ppm detect and identify levels are given for several gases for a 50 meter-wide plume width, that is, the detected gas fills the entire width of an installation where the remote light source is at a 50 meter distance. From this it can be seen that the inherent sensitivity of this device is on the order of 1 ppm for a range of toxic gases.

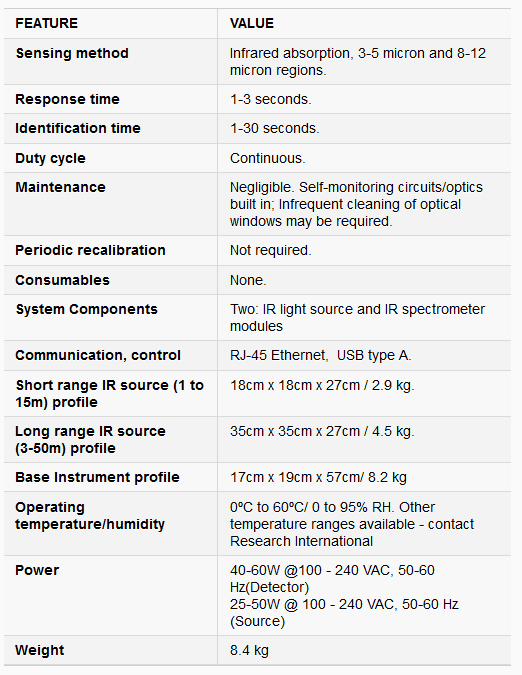

System specifications can be found under the "Specifications" tab above.