- Home

- Companies

- Nordson TEST & INSPECTION

- Products

- Nordson - Model SQ3000™+ - ...

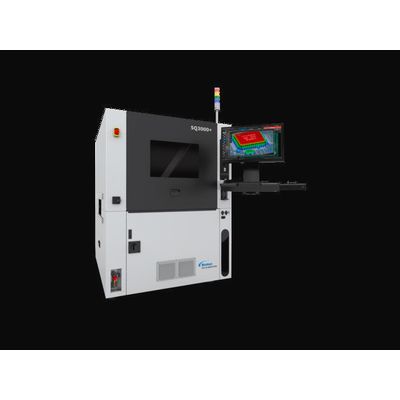

Nordson - Model SQ3000™+ -Multi-Function for 3D AOI, SPI & CMM

SQ3000+ Multi-Function System with Multi-Reflection Suppression® (MRS®) sensor technology provides the ultimate combination of high resolution, high accuracy and high speed for inspection and metrology. It remains the only system on the market capable of performing AOI, SPI and CMM in-line.

Ultra-High Resolution, 5 Micron - Multi-Reflection Suppression (MRS) Technology

SQ3000+ offers unmatched accuracy with the advanced MRS sensor technology by meticulously identifying and rejecting reflection-based distortions caused by shiny components and surfaces. Effective suppression of multiple reflections is critical for accurate measurements. The new, ultra-high resolution 5 micron MRS sensor incorporated into the SQ3000+ is specifically designed for advanced applications with the most demanding requirements.

Inspection and Metrology Solution for Assembly and Process Improvement for Advanced Applications

Intuitive, Easy-to-Use Software - Enable Smarter, Faster Inspection

Speed programming and tuning with new capabilities including AutoTeach, AutoTune and AutoDefine for faster set-up and a simplified process. AI² (Autonomous Image Interpretation) technology is all about keeping it simple - no parameters to adjust or algorithms to tune. And, you don’t need to anticipate defects or pre-define variance either. AI² does it all for you, powered by a data-rich, pre-loaded library and automated scripts that collect and update models all on their own. With AI², you have the power to inspect the most comprehensive list of features and identify the widest variety of defects. AI² offers precise discrimination with just one panel inspection making it a perfect solution for high-mix and high-volume applications.

Faster, Highly Accurate Coordinate Measurement (CMM) Suite

Powered by Multi-Reflection Suppression® (MRS®) Sensor Technology

The new, ultra-high resolution 5 micron MRS sensor incorporated into the SQ3000+ is specifically designed for advanced applications with the most demanding requirements.

Inspection and Metrology Solution for Assembly and Process Improvement for Advanced Applications

The SQ3000+ with MRS technology is ideal for high-end applications including advanced packaging, mini/micro LED, advanced SMT applications for automotive, medical, military, aerospace and advanced electronics, 008004/0201 solder paste inspection (SPI), socket metrology and other high-end coordinate measurement (CMM) applications where quality and reliability are critical.

- Inspection Speed : 16 cm²/sec (2D+3D)

- PCB Size :

- Minimum: 50 x 50 mm (2 x 2 in.);

- Maximum: 420 x 320 mm (16.5 x 12.5 in.)

- Resolution XY / Z : 5 µm / 0.1 µm

- Maximum Weight (PCB or Sample) : 10 kg

- Component Types Inspected : Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

- pins, and more

- Solder Joint and Other Defects : Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins

- Minimum Component Size : 0201 mm (008004 in.)

- Component Height Clearance : Top: 20 mm ; Bottom: 50 mm

- Field of View (FOV) : 25 x 25 mm

- Min./ Max. Feature Height: : Min. 10 µm ; Max. 400 µm at spec, 2.4 mm capability

- Component Defects : Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more

- Coordinate Measurement

- Capability : Line / Distance / X,Y / Mid Line, Inter Point / Regression Shifted, Datum X,Y / LSF X,Y Offset,

- X,Y Offset / Value / Location / List of X,Y Values, Height / Local Height / Regression / Radius, Coplanarity/ Distance to plane / 2nd Order fitting, Difference / Absolute / 2sqrt / VC, Max / Min / Ave / Sigma / Plus / Minus / Multiple