- Home

- Companies

- ONEJOON GmbH

- Products

- ONEJOON - Retort Kiln

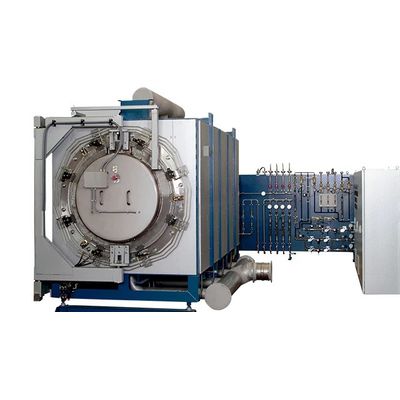

ONEJOON - Retort Kiln

Discontinuous furnace technology for gas phase deposition (CVD) of non-metallic powders and the reduction of metallic powders. The ONEJOON retort kiln is the ideal solution for processes with demanding atmospheres such as silanes (SiH4), hydrogen (H2), gaseous magnesium (Mg), vacuum and many more.

A typical application of the retort furnace is the chemical vapor deposition into non-metallic powders as well as the oxygen reduction of metallic powders to obtain a high purity metal grade.

The retort kiln with its unique process gas circulation, consisting of high process gas velocity and optimal process gas guidance directly over the product, allows a homogeneous flow through the entire product structure, which in turn ensures excellent atmosphere and temperature homogeneity. Due to the high process gas circulation, very short heating and cooling rates are possible without compromising atmosphere and temperature homogeneity.

In order to save additional process gas and minimize the cycle time, the process gas exchange is realized by vacuuming the process chamber and then injecting the process gas.

Since the retort furnace is a discontinuous furnace, the space requirement is small and the layout compact.

With ONEJOON retort kilns different processes can be mapped.

These include, for example:

- vapor deposition (Chemical Vapor Deposition)

- reduction of oxygen

- debinding and presintering

- special processes

The correct heat treatment of high-performance ceramics

The fill structure loaded with the products to be manufactured is transported to the furnace floor and lifted upwards via a lifting portal. As soon as the floor has reached its position under the furnace, both are locked together. To prevent heat from escaping and, at the same time, ensure a gas-tight seal, a floating seal with spring-loaded elements is used. The lifting portal is then used for loading and unloading other parallel furnaces.

During the debinding phase (up to 500 °C), the furnace load is heated by circulating hot air, which has previously been preheated by an external heater. The waste gas contaminated with the binder is cleaned in a thermal afterburning plant. At the end of the debinding phase, further heating is carried out by electrical heating elements in the furnace.

The process gas can also be kept in circulation at elevated temperatures up to 800 °C. This contributes to optimum temperature homogeneity during the heating process. The circulation of the process gas ends at temperatures above 800 °C.

Also in the subsequent process steps, no gas or air circulation takes place until the maximum temperature is reached. This is because turbulence in the furnace atmosphere is often very critical for sintering and crystallisation processes. At the end of the process, the workpieces are cooled with tempered air or gas. For this purpose, an external heating system regulates the temperature of the cooling medium in advance before it reaches the product carriers and the products. After cooling down to approx. 250 °C, the furnace floor is transferred from the lifting portal to a cooling chamber where the products are finally cooled down to room temperature.

- challenging atmospheres (SiH4, H2, Mg etc.)

- excellent atmosphere and temperature homogeneity

- very short heating and cooling rates

- quick and easy loading and unloading

- optimised cycle times

- low space requirement, compact layout

- vacuum-tight retort with inner muffle

- direct process gas injection

- optimised process gas circulation with hot gas fan up to 1000 °C

- powerful indirect cooling

- charging rack for fast loading and unloading

- CFD simulation to optimize the process gas flow