- Home

- Companies

- BW Filling & Closing

- Products

- Pneumatic - Model CB50F - Open Air ...

Pneumatic - Model CB50F -Open Air Integrated Canning Line

The CB Series of integrated filler/seamers provide canning technology designed specifically for and scaled to the needs of craft beverage packaging. Open air or atmospheric filling is cost-effective for still and lower-carbonation products, and is relatively simple to operate and maintain.

The accurate and repeatable fill level metering uses magnetic flow meter technology, with no moving parts. Because sanitation is critical, product contact parts, including CO2 pre-purge nozzles and product contact parts in individual fill valves are made from 316 stainless steel. Product supply piping and connections are all sanitary/hygienic, and of course, product supply is Clean In Place (CIP) capable, up to 180°.

Changeovers are fast and easy, thanks to quick change levers, and tooling adjustments are maintained between changeovers. Even the seaming cam is easy to remove and replace when you are changing material, can size and/or seaming specifications.

- Integrated 6-head inline filler with a single head can seamer provides continuous operation at speeds up to 50 Cans per Minute (CPM)

- Variable speed range of 15 - 50 Containers Per Minute (CPM)

- Integrated 6-head inline filler with a single head can seamer heads

- Tooling adjustments are maintained between changeovers

- Can rinser assembly with air dry

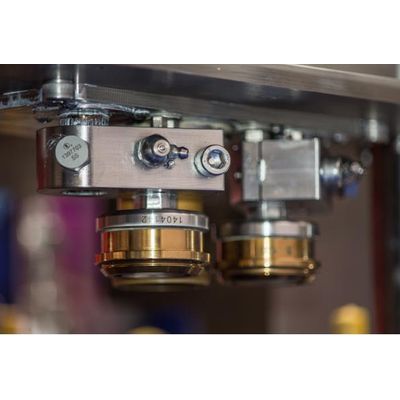

- Seaming tooling design and technology is the reliable, robust Angelus V-series

- Titanium Nitride-coated Angelloy® seaming rolls with ceramic bearings

- Sub-surface filling minimizes product agitation

- Single can indexing prevents disturbing the product and altering CO2 values

- Continuous operation at speeds up to 50 Containers Per Minute (CPM)

- Variable speeds of 15-50 CPM

- Six filling heads

- Simple HMI input for individual fill head volume adjustments

- Cam-operated Can Holding Chuck (CHC)/lower Lifter with adjustable CHC spring

- Grease lubrication

- Hardened tool steel seaming cam for long life

- Stainless steel product area and base assembly

- Sealed for Life (SFL) seaming rolls available

- Seaming cam optimized for beverage applications

- Seaming cam easily removed/replaced for possible future changes in material, can size and/or seaming specifications

- Seaming levers designed with the specific material and dimensions, allowing torsional windup for superior double seam formation

- Quick change levers for repeatable changeovers

- Tooling adjustments maintained between changeovers

- Can rinser assembly with air dry

- Angelus V-Series seaming tooling design and technology

- Titanium Nitride-coated Angelloy® seaming rolls with ceramic bearings

- Individual Zerk fittings for manual lubrication of seaming rolls

- Protective flange to prevent damage from maladjustments

- Sealed for Life (SFL) seaming rolls available

- Accurate and repeatable fill level metering using magnetic flow meter technology, with no moving parts

- Sanitary 316 stainless steel CO2 pre-purge nozzles

- Individual fill valves with product contact parts made from 316L stainless steel

- Integrated flow control valves with easy pneumatic pressure adjustment for clean fills

- Sanitary/hygienic product supply piping and connections

- Product supply Clean in Place (CIP) capable, up to 180 degree temperature rating

- Integrated 6-head inline filler with single head can seamer rated for continuous operation at speeds up to 50 Cans per Minute (CPM)

- Variable speed range of 15-50 CPM

- Optimized for beverage can height range of 2.13” - 8.00”

- Six individual filling heads utilizing magnetic flow meter technology, with no moving parts

- Simple HMI input for individual fill head volume adjustments

- Filler designed with quick-change adjustments for easy changeover for various can height/body diameters

- Under Cover Gassing (UCG) at lid applicator chute

- Cam-operated Can Holding Chuck (CHC) / Lower Lifter with adjustable CHC spring

- Grease lubrication

- Hardened tool steel seaming cam for long life

- Stainless steel product area and base assembly