- Home

- Companies

- Novacam Technologies

- Products

- Optical 3D Profilometer System

Optical 3D Profilometer System

NOVACAMTM OPTICAL 3D PROFILOMETERTM system is fiber-based and provides: Micron-precision 3D measurements: Dimensional geometry – GD&T parameters, Roughness measurement, Defect detection – cracks, scratches, Thickness measurement of semi-transparent materials. Option to scan even hard-to-reach surfaces: Side-looking probe scans inside bore IDs and other tight spaces, forward-looking probe is also available. Fiber-based probes that are easy to integrate with precision stages, third-party CMMs, CNC machines, or robots to support high-volume continuous flow manufacturing. Fully configurable automated inspection. Notably the same probe can be used to measure dimensions, roughness, defects, and/or thickness.

- Optical, non-contact, non-destructive

- High speed: Up to 100,000 3D point measurements per second

- Micron resolution, excellent S/N ratio

- 2D and 3D surface and subsurface characterization

- Dimensions, roughness, defects, thickness

- Long stroke profilometry

- Surface profiles

- Cross-sections

- Volumetric images

- Inspect inside bores, tubes, and crevices

- Provide versatility for high-speed online inspection

- Wide range of materials: metal, plastics, polymers, glass, metal coatings, silicone, adhesives; reflective, transparent, semi-transparent, specular, nonspecular

- Wide range of surfaces: measured objects can be stationary or moving, solid or liquid, and include interiors of bores and tubes, exteriors of cylinders, concave or convex spherical shapes

- Small-diameter probes reach in to measure insides of bores and small-diameter tubes

- Measures high-aspect-ratio features: undercuts, cross-holes, chamfers, rifling, threads, O-ring grooves, and edges

- Reduced inspection cycle time: up to 100,000 measurements per second, each representing a 3D topographic point

- Versatility of setup: Non-contact probes work up to 1 m away from surface and several meters from the interferometer

- Continuous, long profile scanning: no area stitching required

- Flexible options for evaluating inspected parts: measured features can be compared to CAD drawings or to a user-defined set of locations, nominals, and tolerances

- Simple scan definition and execution: The scanning sequence is defined once by teaching the system with a joystick. The scanning sequence can later be executed with the push of a button.

- Time-saving automated reporting: Following a scan, go-no-go reports can be produced, and results logged in a manner compatible with industry-standard mechanisms

- Easily integrated in lab, shop, or fully-automated inspection setups: probes may be mounted on XY tables, on multi-axes scanning mechanisms, inside machining centers, above moving webs, on robot heads, etc.

- Adaptable to hostile environments: radioactive, very hot, cryogenic, vacuum, etc.

- No consumables are needed: Optical probes do not come in contact with the measured samples, and therefore do not wear out like contact probes

- USB connection for data transfer from interferometer to PC or laptop

- Option of multiplexing several probes with single interferometer for additional return on investment (ROI)

Typical measurements

- Dimensional measurements: geometric dimensioning and tolerancing (GD&T) parameters

- Thickness: single-layer or multilayer films, coatings

- Surface roughness: surface characterization, flatness, and more

- Volume loss: component wear or other damage

- High-aspect-ratio features: steps, holes, grooves, channels

- Hard-to-reach spaces: interiors of bores, small aperture tubes, etc.

- Profilometry in hostile environments: radioactive, cryogenic, very hot

- Long stroke profiles

- Thickness of non-transparent materials

3D metrology and imaging for industry and R&D

- Quality control

- Online 3D production inspection, GD&T

- Statistical process control SPC

- R&D

Examples of applications

- Electronics industry: geometry measurements of CMP pad grooves, glass edge and thickness measurement, wafer geometry

- Aerospace: jet engine turbine vanes

- Automotive: drive shafts, axles, threads, splines, gears, drive teeth

- Medical instruments sector: tubes, implant shaft interiors, optical cross-sections of intra-ocular lenses

- Biomedical and chemical sectors: vials, IDs of cylindrical containers

- Defence industry: barrels, bores, reamers, mandrels, drill bits, die blocks

- Tubular parts in high-precision machining, drilling, injection molding, 3D printing, additive manufacturing, casting, extrusion dies

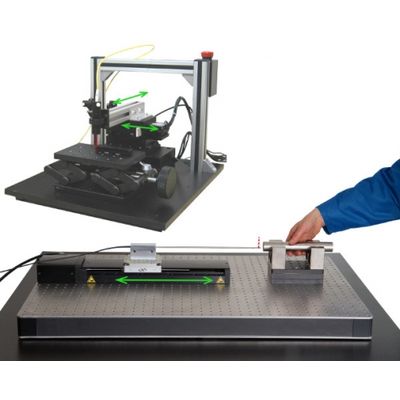

Standard system configuration

A standard configuration of the OPTICAL 3D PROFILOMETER system includes:

- MICROCAM-3D interferometer

- Choice of

- 1 standard ?17.8 mm forward-looking probe

- OR

- 1 standard ?4.6 mm side-looking probe (for ID up to 300 mm (12″) deep)

- 2-axis inspection station and 2-axis motion controller

- Manual adjustment of probe height

- PC with NOVACAM acquisition software

- 1 year warranty

- MICROCAM systems feature an in-probe red laser pointer (650 nm wavelength) for alignment purposes.

- MICROCAM systems are Class 1M Laser products, with < 20 mW of infrared and < 5 mW of in-probe laser pointer.