Sludge Disposal Challenges

Across industries — from refineries and petrochemicals to fertilizer plants, steel mills, power plants, and wastewater treatment facilities — sludge is a constant by-product of operations. But sludge is not just waste; it often contains valuable trapped liquids like oils, water, acids, and solvents.

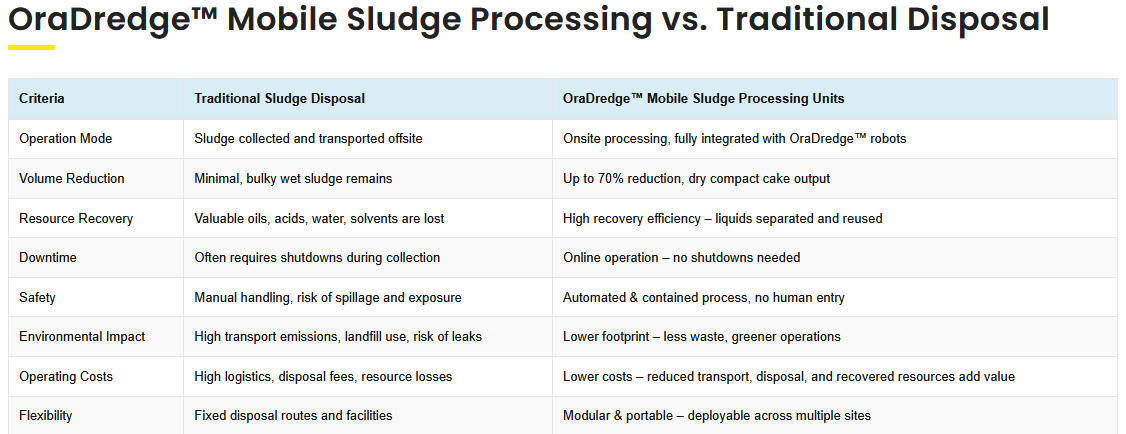

The challenges of conventional sludge disposal include:

- High transport and handling costs due to bulky, wet sludge.

- Loss of valuable process liquids that remain trapped in sludge.

- Environmental compliance risks with untreated sludge disposal.

- Downtime when sludge cannot be processed onsite.

Traditional approaches often involve collecting wet sludge and transporting it offsite, which is both costly and unsustainable.