- Home

- Companies

- Wuxi Enviclone Test Equipment Co., Ltd.

- Products

- enviClone - Model EVCL - Ozone Aging ...

enviClone - Model EVCL -Ozone Aging Test Chamber

enviClone Ozone Aging Test Chamber simulates and intensifies the ozone conditions in the atmosphere. During the test, the test specimen inside the ozone aging test chamber will be under dynamic or static tensile deformation and will be exposed to a closed environment with constant ozone concentration and constant temperature without light and will be tested at a predetermined time.

According to the degree of cracking or other performance changes on the surface of the test specimen, the ozone aging resistance of rubbers can be quickly identified and evaluated, and then users can take corresponding protective measures to improve the service life of rubber products.

In the ozone production process, the technical indicators such as the concentration value, output and production efficiency of ozone gas are greatly affected by the temperature, humidity and pressure of the gas source, the cooling efficiency of the generator, the aging of the discharge chamber along the discharge surface and other factors. Therefore, the installation and use of concentration detection devices on ozone application equipment is a necessary technical means to achieve online continuous monitoring, precise control of ozone gas concentration, and calibration of ozone production. After the ozone concentration probe is installed, the automatic control of equipment operation can be realized to achieve the best working state of the system, avoiding the shortcomings of low accuracy and poor timeliness of detection data when using manual iodine titration.

The ozone system is mainly composed of a concentration controller, an ozone generator, an ozone analyzer, and an air intake system; by setting the ozone concentration on the controller, the ozone analyzer transmits the detected real-time concentration to the controller, and the controller sends the actual The value is calculated and compared with the set value, and the P.I.D. intelligent output signal controls the working time of the ozone generator, so as to achieve the purpose of real-time control of the ozone concentration.

Brief operation steps:

- Connect the switch. At this time, the temperature controller will display the temperature in the chamber.

- Press the panel power switch to start the device, then press the ozone button to set the ozone concentration and temperature, adjust the temperature control switch to the temperature to be protected, and set the time.

- Fix the sample on the turntable fixture, adjust the bolt, and set the stretching length.

- Close the door, start the test program, and automatically conduct the ozone aging test.

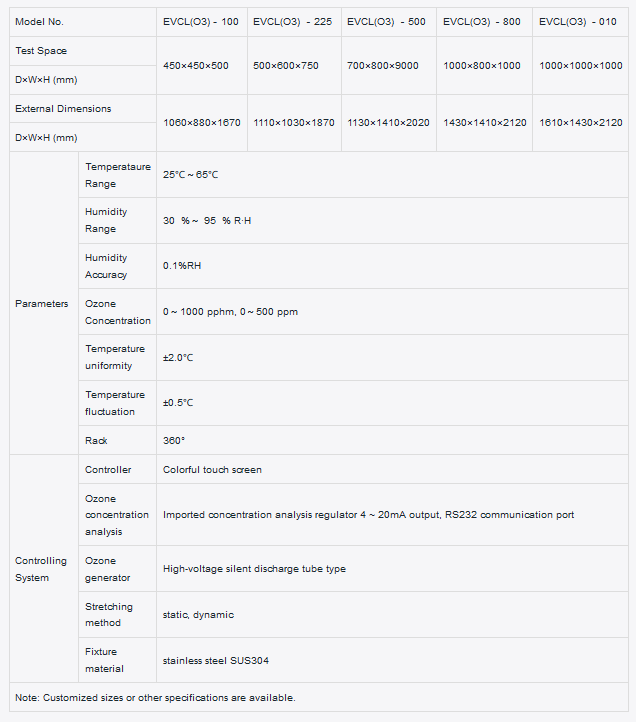

- Customized sizes are available.

- On-site installation and training for customized ozone aging chambers are available.

- It adopts the design of non-ozone waste gas external discharge, environmentally protective and eco-friendly.

- Quality performance, it can continuously work for as long as 7,000 hours.

- With dual dynamic and static tensile tests.

- With touch-screen programmable controller, easy to set test process and get access to test data as well as records.

- External chamber material made of high-quality A3 steel plate, thickness 1.2mm (or customized thicker), and the surface is sprayed with plastics, which is smoother and neater. Internal chamber material: high-grade stainless steel (SUS304), anti rust.

- Insulation material: rigid polyurethane foam + glass fiber, with perfect insulation performance.

- With multiple protective designs for user’s safety: Fault alarm and cause, processing prompt function, Power-off protection function, Upper and lower limit temperature protection function, Calendar timing function (automatic start and automatic stop operation).

- Test chamber comes with all instructions: Certificate of Conformity, Warranty Card, Circuit Diagram, English Manual

Ozone System