- Home

- Companies

- ERG (Air Pollution Control) Ltd

- Products

- ERG - Packed Towers Scrubbers

ERG - Packed Towers Scrubbers

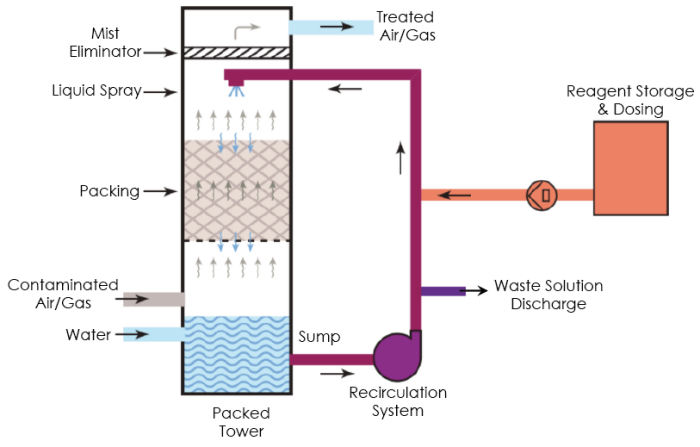

Packed tower scrubbers are a highly efficient way to remove soluble contaminants from air and other gas streams. Packed towers are also used for stripping contaminants from liquid streams and for direct contact cooling of gas streams.

Most popular related searches

packed tower scrubber

packed tower

air pollution control

air pollution control system

tower scrubber

pollution control system

tower packing

scrubbing system

air pollution

air pollution control industry

- Used for high efficiency mass transfer (scrubbing and stripping) or heat transfer (gas cooling)

- All ERG designs are bespoke and matched to the detailed requirements of the application specification

- ERG uses industry-standard random packing to optimise operating efficiency with system pressure drop and equipment size

- All packages carry a performance guarantee and are designed to provide robust operation at the lowest capital and operating costs

Our extensive design and operating experience enables us to optimise the system performance.

- Flowrate ranges from 100 to 100,000 m3/hr per tower, multiple towers in parallel can be used for higher flowrates.

- Contaminant loadings depend on type, with typical inlet loadings ranging from 100 mg/m3 up to 100,000 mg/m3.

- Typical removal effeciency 99.5% up to 99.95% as required.

- Vessel diameters from 200 to 3,800 mm, heights typically up to 10 m or higher if the process requires it.

- Removal of any soluble gaseous contaminant.

- Cooling saturated gas streams from typically 60 to <30 oC; or as required.

- Complete systems supplied including recirculation pump, pipework, fan, ductwork, access platform, instrumentation and control system – and may be integrated further with other ERG mass/heat transfer equipment (e.g. quench, venturi, carbon filter, etc.) into a single Air Pollution Control solution

- Commonly used packing types include Snowflake / Astra PAC and 1″, 1.5″ and 2″ Pall rings

- Recirculated liquor flowrate selected to minimise pump flow and energy consumption at optimal scrubbing performance

- Liquor distribution across packing using sprays, trough or ladder distributors depending on application

- Droplet elimination using chevron, impaction blade or woven mesh design to suit application – clean in place sprays available to assist with on-line maintenance

- Scrubber sump tank integrated into the packed column vessel

- Chemical dosing, water make-up and blowdown control to match specific performance requirements

- Instrumentation selection to give robust operation, high reliability and tight performance control

- System control by stand-alone MCC/C&I panel or integrated DCS, with HART or Profibus protocols available as standard

- Vessels designed as standard to PD 5500 (metal) and BS EN 13121 BS 4994 (GRP) with CE marking to PED as appropriate. Other design codes are available as required

- Materials selection to suit contaminants and reaction chemistry: common materials include uPVC, PP, cPVC, Derakane® GRP, Crystic® GRP, 304SS, 316SS

- Heat transfer using in-line heat exchangers

- HCI scrubbing using water/dilute HCI solutions to recover HCI for reuse

- HCI scrubbing using NaOH solution to achieve extremely low discharge concentrations

- SO2 scrubbing using NaOH solution – for scrubbing with lime click here

- H2S scrubbing using NaOH and NaOCI solution

- NH3 scrubbing using dilute sulphuric acid solution

- VOC scrubbing using water or mineral oils