- Home

- Companies

- Jiangxi Aite Mass Transfer Technology ...

- Products

- AITE - Packing grid Cooling Filler ...

AITE - Packing grid Cooling Filler Packing

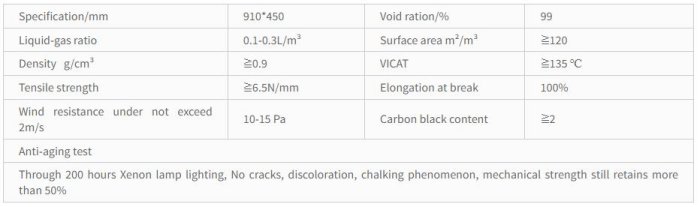

It is constructed by a series of plastic sheets assembled into a lattice structure, with its internals engineered to the geometry of honeycombs. This network structure provides a large contact area which allows even liquid distribution, augmenting liquid flow rate with minimum resistance. Its high surface area to volume ratio contributes to high mass transfer efficiency. Structured packing media is versatile and can be stacked into block-form, suitable for use in towers. Made of Polypropylene (PP) in colour black. Cooling Tower Fills Splash Fill Wet Net Filler Structure Packing grid.

Horizontal ventilation Mode:

When Exhaust in pig farm passing Fan to Washed filter wall,Exhausts humidity will increase by be spayed and form air & liquid mixing.Partly of Ammonia and dust will be absorb by droplet and fell down the reservoir.Hydrogen sulfide and ammonia and so on will be grasped by Biological bacteria attached on wet net filler module and decomposed. Therefore, Exhaust will be purified.

In order to ensure the activity of biological bacteria, the spray system will automatically adjust PH, spray volume, water replenishment volume and so on based on PH,LF test equipment’s test data. This adjustment keeps Biological bacteria’s Long-term & effective activity

Longitudinal ventilation:

The working principle is same with horizontal ventilation.The biggest difference is air flow direction.Longitudinal ventilation can extend the vertical channel height and increase wet net filler module thickness.

In big pig farm or livestock farm with large displacement,Two mod integrated application will achieve outstanding Deodorizing effect.