Jiangxi Aite Mass Transfer Technology Co., Ltd. products

Tower Internals

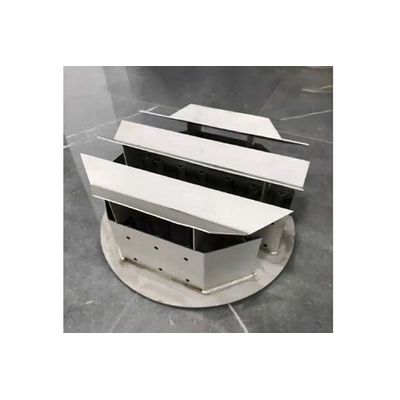

AITE - Liquid Collection Redistributor

Liquid collector’s major function is collecting the liquid and re-distributing the gas. Usually, liquid collector is in the top of packing bed. The distance between liquid collector & packing bed is 150-200 mm.When the liquid falling down along with packing,due to upward gas’s speed is not same, gas’s speed toward center is big and toward tower wall is small. It is very easy to form wall flow phenomenon. In order avoid of wall flow phenomenon’s happened and improve mass transfer efficiency, we should install liquid collector or liquid re-distributor to improve liquid’s evenly distribution. Of course, according to different processing requirement, we can install one or many Liquid collectors in the different height’s position.

VOCs

AITE - Ceramic Ring Media

It is an ideal support media.Owing to its unique structure enables an upper support layer with a typical diameter of 11.5 mm to effectively retain a bed of 1.6 mm catalyst without any migration into the support layer. This eliminates the need for micro-sized spherical support balls,ceramic ring media reduces the number of support layers needed, reduces pressure drop and increases the space available for catalyst or adsorbent in the process reactor. In addition, Wave type shape ensure sufficient gaps between the packings to promote air’s freedom flow. Also overcome packig bed’s unevenly heat destribution phenomenon happening. ceramic ring media

Cooling Tower Filler

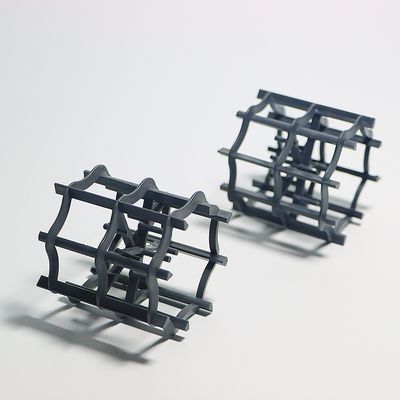

AITE - Packing grid Cooling Filler Packing

It is constructed by a series of plastic sheets assembled into a lattice structure, with its internals engineered to the geometry of honeycombs. This network structure provides a large contact area which allows even liquid distribution, augmenting liquid flow rate with minimum resistance. Its high surface area to volume ratio contributes to high mass transfer efficiency. Structured packing media is versatile and can be stacked into block-form, suitable for use in towers. Made of Polypropylene (PP) in colour black. Cooling Tower Fills Splash Fill Wet Net Filler Structure Packing grid.

Tower Random Packing - Ceramic Random Packing

AITE - 50 Ceramic Intalox Saddle Rings, Washing Tower

Compared with Ceramic Berl Ring, it changes the both arched surface to rectangulor surface.This change increases packings contacting gap and promotes air-liquid’s flow and dispersion. Owing to Ceramics have excellent acid and high temperature resistance characteristic, it is very suitable in High temperature and corrosive environment. In addition,as ceramics are very brittle, it is very easy to broken in a long distance transportation. Ceramic Intalox Saddle Rings washing tower It is mainly used in petrochemical and RTO field, especially in the drying tower and absorption tower for sulfuric acid production.Ceramic Intalox Saddle Rings washing tower

Plastic Random Packing

High Efficiency Plastic Teller Rosette Ring for Scrubbing Tower Packing

The Plastic Teller Rosette Ring is designed for optimal performance in gas absorption, mass transfer, and liquid particle removal within scrubbing towers. This high-efficiency packing material comes in various sizes including 25mm, 47mm, 51mm, 73mm, and others, and is manufactured using materials such as PP, PVC, PFA, PE, CPVC, PVDF, PPS, PES, E-CTFE, and FRPP. It is engineered to promote the regeneration of liquid surface areas, thus enhancing gas absorption efficiencies. The ring's filamentous toroidal helix shape aids in the collection of solid and liquid particulates, minimizes pressure drop, and eradicates the need for liquid redistributors by promoting circular motion of the liquid, thereby overcoming the tower wall effect. Typical applications include degassing and deodorization towers, absorption and distillation towers, water treatment facilities, and absorbers. It adheres to the HG/T 3986-2016 executive standard and offers flexible packaging options including super sacks, plastic woven bags, and cartons on fumigation pallets.Plastic VSP Ring for Gas and Liquid Interface Processes

The Plastic VSP Ring offered by Ayrtter is designed for various mass transfer applications including water treatment and exhaust-gas cleaning. This tower packing material is primarily made from robust materials like PP, PVC, PFA, PE, CPVC, PVDF, PPS, PES, E-CTFE, and FRPP. Its honeycomb lattice structure ensures even liquid distribution and optimal flow rates with minimal resistance. Known for its high surface area to volume ratio, it promotes efficient mass transfer and is particularly effective in scrubbing and stripping volatile organic carbons (VOCs) and other gases. The product is used in various applications including the absorption and neutralization of acidic gases such as HCL, SO2, and NOXs, as well as hydrogen sulfide absorption in wastewater treatment plants. The VSP Ring also finds use in degassing applications, effectively removing carbon dioxide and radon, and oxygenating water for aquaculture. Its open design minimizes fouling and ensures good liquid and gas distribution, providing low pressure drop, high capacity, and high heat transfer efficiency.Structured Packing

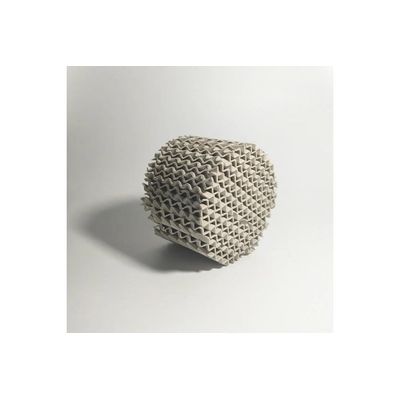

AITE - Ceramic Corrugated Plate Packing

It is constructed of corrugated sheets of ceramic.The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, form mixing cells at every point where the corrugation intersect.High temperature and corrosion resistance Ceramic Corrugated plate packing