Paladex Tubes

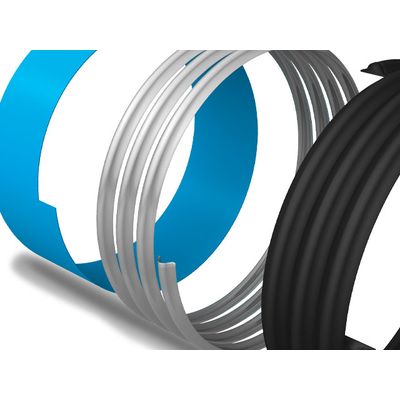

The PALADEX ® tube is made through a continuous helical winding process of polyethylene and steel, suitably shaped with an omega profile. The combination of the two materials together with the choice of the omega profile gives the PALADEX ® pipe characteristics and performance that are clearly superior to structured pipes in thermoplastic material and other pipes on the market with the same intended uses (fibreglass, concrete, cast iron, stoneware, etc.).

Furthermore, the particular and innovative structure gives the PALADEX ® tube , with the same annular rigidity, a lower weight than tubes with the same intended uses on the market.

The average weight of a PALADEX ® DN/DI 1200 SN8 spiral pipe, in fact, is equal to 70 kg/m, that of a classic polyethylene spiral pipe is equal to 120 kg/m and that of a reinforced concrete pipe is greater than 1900 kg/m.

Paladex ® technology is created through a continuous helical winding process of polyethylene and galvanized steel shaped with an omega profile with the innovative Biadhesive Bonding Process (BBP) adhesion system for fixing the elements.

The section of the pipe is made up of an internal layer of polyethylene, an external wall structured in polyethylene and a core of galvanized steel covered with a polyethylene-based primer which guarantees perfect homogeneity and adhesion of the constituents.

Paladex ® technology represents the evolution of the production technique of galvanized steel reinforced polyethylene spiral pipes originally developed in Japan in the nineties and widely used today.

This progress allows the creation of large pipes and tanks characterized by extremely high mechanical resistance and low weight. The combination of the two materials together with the choice of the omega profile gives PALADEX ® pipes characteristics and performance that are clearly superior to structured pipes in thermoplastic material, fibreglass, concrete, cast iron and other traditional alternatives.

Added to the intrinsic cost-effectiveness of PALADEX ® technology pipes are the significant savings inherent in the cost of transport, handling and installation which favor significant savings in the construction of infrastructures.

Paladex ® technology , created by an ISO 9001:2015 certified company , obtained the mark of conformity to the Italian UNI 11434 regulation in June 2012 .