- Home

- Companies

- Beijing PFM Screen Co., Ltd.

- Products

- PFM - Model BOM - Paper Machine ...

PFM - Model BOM -Paper Machine Clothing Double Layer Press Felts

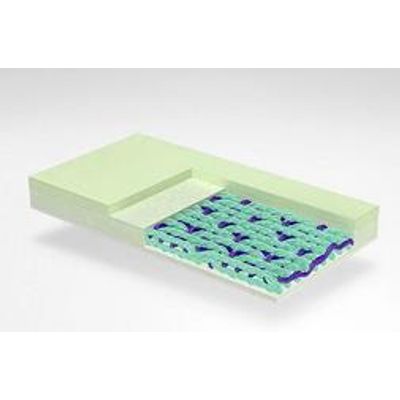

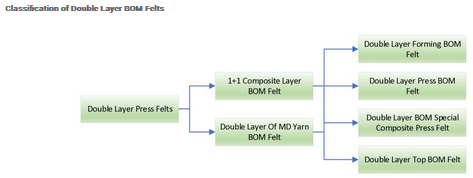

Double Layer Press Felts include a 1+1 composite structure and a double layer of MD yarn structure. The 1+1 composite structure consists of two-layer base meshes of different thicknesses. Both of these base meshes can be changed in construction and sizes to suit the requirements of different paper machines. Double layer felts have the features of high press resistance, good flexibility, permeability and size stability, less elongation, excellent tensile strength. The felts are also resistant to vacuum marks, blind hole marks, groove marks, etc.

Double-layer BOM felts are used in press types such as groove press, vacuum suction press, multi-press, large-diameter nip-roll press to produce high-grade printing papers, news-prints, technical papers, packaging papers, high-grade paper boards, etc.

- Double-layer base fabric

- Widely applicable

- Large void volume

- Resistance against high-pressure loadings

- Good flexibility

- Excellent permeability

- Remarkable structural stability

- Less elongation

- Excellent tensile strength

- None vacuum marks, blind hole mark, groove mark

Applied to press types: groove press, vacuum suction press, multi-press, large diameter nip-roll press to meet the production of high-grade printing paper, newsprint, technical paper, packaging paper, high-grade paper board etc.

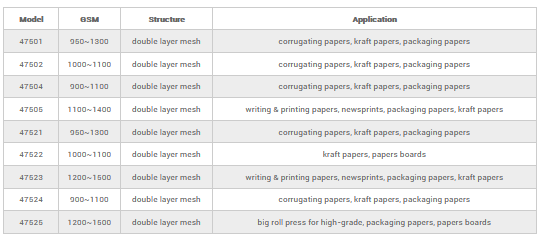

Paper machine: Multicylinder, super forming, superposition wire, nip wire paper making for different kinds of paper machine’s press felt and forming felt.

- Paper machine velocity: ≤1000m/min

- Paper: ≥8g/m2

- NIP: 60-200KN/m