- Home

- Companies

- Ringo Valvulas S.L

- Products

- Parallel Slide Gate Valves

Parallel Slide Gate Valves

For those applications when large temperature variations are expected or fast shutt-off is required, this is the most ideal design. The seats are parallel and the disc has no contact with the seats during the stroke of the valve. Only at the end of the stroke the disc mechanism ensures the contact between seats and disc.

Optional features:

- Lantern ring

- Equalizer

- Locking device

- Stem extension

- Leak-Off & Packing Expulsor

- Low emission packing

- Non rising stem

- Bellows seal gate

Operation:

- Manual / MOV / AOV / HOV / Electrohydraulic

Types:

Wedge Gate/ through conduit / Double expanding

Construction:

Bolted bonnet / Pressure seal

Disc type:

Solid / Flexible/ Split /Parallel slide

Standard features:

OS&Y / Backseat

Materials:

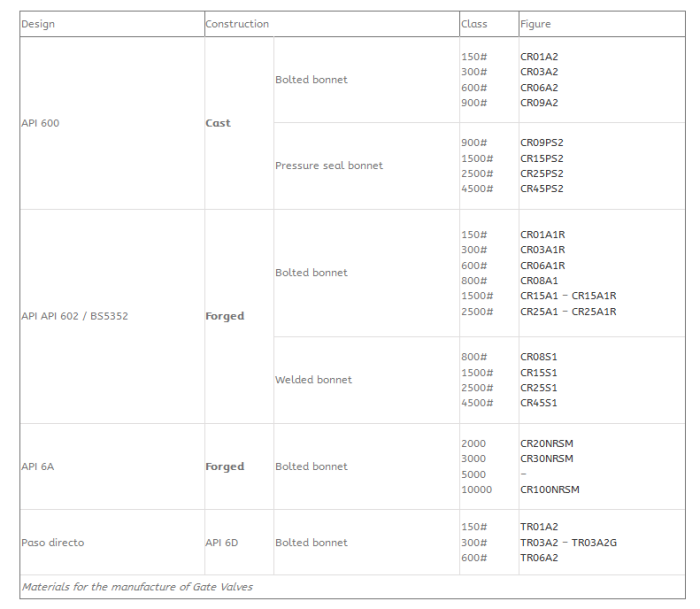

Ringo Válvulas gate valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications

The main features of our Check valves can be:

- Bolted bonnet

- Pressure seal bonnet

- Thread in or welded bonnet

- Cast or forged

- Swing check, piston check, ball check

- Welded in or replaceable seats

- Dual plate check valves