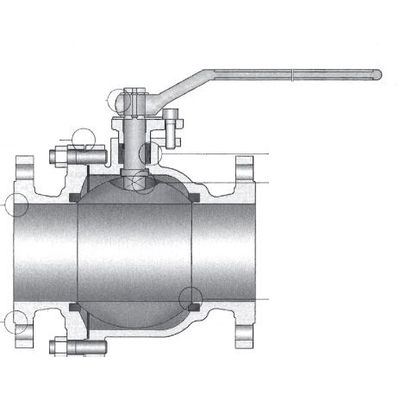

Pasco - Model CS & FL -Ball Valve

PASCO steel ball vaive are designed and manufactured to provide maximum service life and dependability. All bail valves are full ported and meet ihe design requirements of American Petroleum Institute Standard API 608 & API 6D. British Standard 3S 535iand generally conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims.

Range of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels. For special apolications Ihey can be supplied in other grades ot alloy and stainless steell. There`s a full range ol trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions.

Available Modifications for PASCO Steel Valves

- Trim Changes

- End Connection Modifications

- Packing and Gasket Changes

- Operator Mounting

- Handwhael Extensions

- Pressure Equalizing

- AS or FD

- Customer Specified Coatings

- Weld End Sore Changes

- Oxygen & Chorine Cleaning & Packaging

Operating

Extended lever for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services.

Bore

Full Bore or Reduced Bore. Full-bore design provides exceptional flow control.

Packing

STD Packing Multiple V-TEFLON packing, combined with live loading, maintains packing compression under high-cycle and severe service applications. Graphite packing use situation for high-temperature.

AS

Anti Static. A metallic contact is always granted between ball and stem / body to discharge eventual statics build - op during service.

Body & Bonnet

Split or 3-piece. split body & bonnet for 12` & Small. Disassembles easily for repair or replacement of internal components.

End Connections

A choice of Flanged , RTJ flanged or Buttwelding end for piping flexibility.

BPS

Blow-out Proof Stem. A pressure-safe stem shoulder design that protects against failure under excess pressure.

FD

Fire Durable. Designed to API 607 or BS 6755 to grant their operation suitability in case of fire. Secondary metal-to-metal seal acts as backup if primary seal is destroyed by fire. Valves ordered for compliance with API 607 will be provided with graphite packing and gaskets.

- Steel Ball Valves, API 608/API 6D

- Steel Ball Valves, ISO 14313

- Fire Durable, API 607

- Antistatic, API 608

- Steel Valves, ASME B16.34

- Face To Face, ASME B16.10

- End Flanges, ASME B16.5

- Buttwelding Ends, ASME B16.25

- Inspection and Test, API 598/API 6D