- Home

- Companies

- Pollution Control Products Co.

- Products

- PCPC - Burn Off Oven Process

PCPC - Burn Off Oven Process

Powered by clean natural gas, Pollution Control Burn-Off Ovens are virtually Pollution-Free. Contrary to popular belief, our burn-off ovens provide a much cleaner and environmentally-friendly method of cleaning. We do not use acids or other toxic chemicals, and the amount of ash that the ovens produce after the burn-off process has completed is at most a handful amount. Our burn-off ovens are built with abrasion material, with quality in mind as well as pollution control & reduction. That is why our ovens comply with the EPA, and we help you obtain the necessary Air Permit that your state requires.

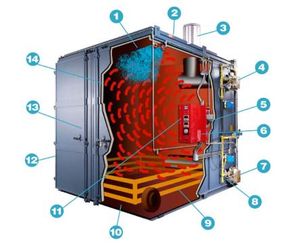

The primary functional components of a burn-off oven are:

- The primary cleaning chamber

- Primary heat input burner, housed in the combustion chamber

- Afterburner, housed in the combustion chamber

- Water cooling system, located in the primary cleaning chamber

- Control panel housing thermal diagnostic and control instrumentation

No flame actually contacts the part

On our furnaces, the primary heat input burner fires into a combustion chamber, which contains the flame, so that only heat is discharged into the work area containing the parts. No flame actually contacts the parts. Other than the air required for combustion of the input burner fuel, no additional air is added to the furnace. Therefore, the oxygen content within the furnace is reduced to a level that prevents the material from catching on fire. The heat causes the organic material to decompose into vapors and pyrolysis gases which are then processed in a secondary direct-flame afterburner.

Setting Heating Chamber and Afterburner Temperature

At installation, with the furnace empty, the afterburner temperature is set to idle at approximately 1400ºF (760ºC) with the main heating chamber set at 800-900ºF (426-482ºC). The temperature is maintained by adjusting the air and gas flow rates to the afterburner during an “empty test run” when the furnace is first installed. Once adjusted, the afterburner will then operate at about the same temperature each time the furnace is started.

Pyrolysis vapors and pollutants are consumed

Since the materials processed in the furnace are cured, they do not give off any flammable vapors at room temperature, and most will not begin to breakdown to any significant extent until they are heated to temperatures above about 600ºF. When the furnace is loaded the material begins to decompose once the furnace reaches a temperature of 600-700ºF (315?371ºC). As the material starts to decompose into vapors, these vapors exit through the afterburner chamber where they burn raising the temperature of the afterburner exhaust gases.

The Water Cooling System and Afterburner control rate of processing

When the volume of vapors entering the afterburner chamber drive the exhaust gas temperature up to its set point of 1600ºF (871ºC), the furnace water sprays are activated to cool the furnace and the parts, slowing the evolution of vapors to the afterburner. This cooling process prevents overwhelming the afterburner with large amounts of vapors and pyrolysis gases.

When all of the organic material has been removed from the parts, the afterburner temperature will drop back down to its idle point. Thus, the processing rate of the organic material is strictly limited by the size of the afterburner. During processing, only small amounts of water vapor and carbon dioxide exhaust into the atmosphere leaving only a light coating of ash on the cleaned parts.

-

Pollution Control`s patented Controlled Pyrolysis® water spray system controls the rate of vapor emissions, which prevents an ignition or over-heating conditions in the oven.

-

Explosion Relief Door automatically opens to relieve excess pressure, then closes, preventing air from reaching combustible materials. Vapors are prevented from entering factory area.

-

The Vent Stack is made of easy-to-assemble stainless steel with high-temperature ceramic fiber in hard form. Discharge effluent consists primarily of carbon dioxide and water vapor, which are invisible, odorless and harmless.

-

The Secondary burner (Afterburner) raises the temperature of the vapors to 1400ºF for 1/2 second to completely burn them before discharge to the atmosphere.

-

Water spray system manifold.

-

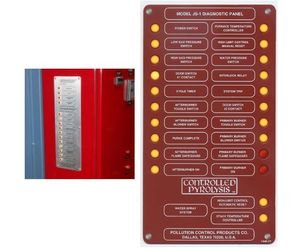

The Diagnostic Panel indicator lights illuminate the start-up sequence and help pinpoint operating problems.

-

The primary heat input burner distributes heat under the cart to heat the metal parts being cleaned. Volatile organic materials are driven off as water vapor and pyrolysis gases. The burner flame is confined to the combustion chamber, never coming in contact with parts.

-

Fuel Line: burners are available for natural gas, propane gas and number 2 fuel oil.

-

Pollution Control manufactures a variety of heavy duty carts designed for specific uses. The carts roll outside the oven on removable tracks for easy loading and unloading.

-

Designed for easy removal of ashes, the floor is 3-4" thick hard castable refractory reinforced with structural steel channels.

-

The Main Control Box houses digital temperature indicator controllers, the main power toggle switch, 2 pilot lights to indicate when the burners are lighted, 0-12 hour cycle timer, part temperature measurement switch and the Diagnostic Panel.

-

The all-welded cabinet is constructed of heavy-gauge sheet steel and supported by structural steel angles and channels with sealed seams to prevent leakage and maximize fuel economy.

-

Doors are equipped with cam-type lock assemblies, tadpole sealing gaskets and stay-open hooks. Doors open 270º.

-

Walls, ceilings and doors are insulated with 3" of double-layered lightweight ceramic fiber blanket, anchored on stainless steel pins, with wire mesh and locking washers. It is protected by a perforated metal liner and is rated at 2300ºF (1275ºC). It contains no asbestos.

Every Pollution Control Burn-Off oven comes with its own "Serviceman On Board" -- The Diagnostic Panel! Located on the side of the main control box cover, its vertical rows of neon lights indicate the operational status of the oven and its individual controls. The Diagnostic Panel not only shows the sequence of start-up -- each neon light illuminates as its particular switch or relay is energized -- it also works as a troubleshooter. When lights fail to illuminate, it helps pinpoint operational problems should they occur.