- Home

- Companies

- CPM Europe BV

- Products

- Pelleted Feed Coolers

Pelleted Feed Coolers

Counterflow coolers have been an industry standard for over 20 years in pelleted feed. In the last 10 years they have also become popular in many other applications for cooling of granular products and meal. The advantages in footprint, energy efficiency, maintenance costs and investment costs have made this type of cooler the preferred choice for nearly every user of pellet mills, flaking mills, expanders, extruders, heat treatment systems, conditioners etc.

The CPM Counterflow cooler is the most reliable and strong Counterflow cooler available. With a wide range of different discharge systems, grid sizes, bin wall heights, cyclones and air fans, there is a customized solution available for every type of product and every cooling requirement.

All CPM Counterflow coolers are built to high specifications. Cooler hood and bin walls are always in stainless steel to prolong lifetime and guarantee clean operation. Air systems can be designed to meet your specific cooling needs.

- Intermediate cooling deck to buffer product temporarily when switching to a new recipe.

- This avoids loss of time and capacity during a change over.

- Air flow control valve which automatically stabilizes air volume in the cooler, indepen-dent of fluctuations in pressure drop.

- Clam shell inlet valve to temporarily store small quantities of fat sprayed product to allow the fat to be absorbed by the hot product before cooling begins.

Product Flow

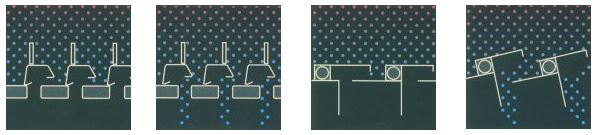

For granular products, Counterflow coolers typically operate in a continuous, First In First Out mode with the discharge system slowly discharging product into the hopper, based on signals received from a product sensor in the bin walls. However, for meal type products it is necessary to apply fluidization of the product bed in order to get sufficient air to flow through. As a result it is better to cool in batch mode, usually in two steps, to allow each batch to be fluidized for a pre-set period of time. Discharging is therefore no longer driven by the product sensor, but by timers.

There are several different types of main discharge systems available:

- The Triple Grid discharger is typically used for easy-flowing, pelleted products.

- This cooler is the ultimate in simplicity, there is just about nothing that can go wrong.

- Product Flow is First In First Out, with gradual discharge into the hopper.

- The Swivel Valve discharger can be applied to nearly every type of product, including those that have very difficult flowing characteristics.

- Bridging and blocking cannot occur with this discharger.

- It also conforms to the highest sanitary requirements.

- Here also, product flow is First in First Out.

- The Batch Discharger is used to dump its entire product bed in one movement.

- Used typically to cool meal or mash type products, its opening sequence is timer driven.

One of biggest selling points of all CPM Counterflow coolers is the fact that they run reliably with an absolute minimum of maintenance. There are just a few electrical items to be connected and no wear parts.

- High hygienic standards

- High energy efficient

- Little maintenance

- Low operating costs

- Low investment

- Limited space required

- Easy installation

- Easy operation

- Easy cleaning

- Long lifetime