- Home

- Companies

- CPM Europe BV

- Products

CPM Europe BV products

CPM - Pelleted Feed Conditioners for Pelleting Systems

CPM offers you the optimum system for your entire conditioning requirement. The optimum conditioning of feed ensures you to get the highest performance out of your CPM Pelleting equipment.

Pelleted Feed Coolers

Counterflow coolers have been an industry standard for over 20 years in pelleted feed. In the last 10 years they have also become popular in many other applications for cooling of granular products and meal. The advantages in footprint, energy efficiency, maintenance costs and investment costs have made this type of cooler the preferred choice for nearly every user of pellet mills, flaking mills, expanders, extruders, heat treatment systems, conditioners etc.

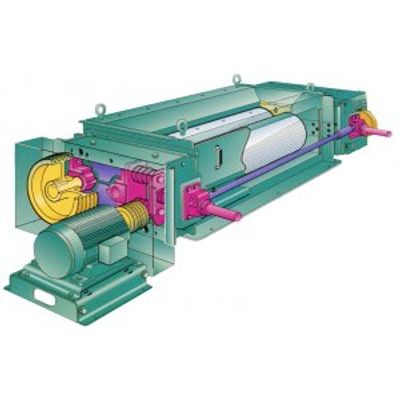

CPM - Pellet Crumblers Machines

CPM pellet Crumblers are high-capacity, high- efficiency machines. The heavy duty design and user-friendly features ensure many years of continuous, reliable operation. CPM pellet crumblers are available in a variety of capacities. As the world`s largest manufacturer of pellet mills, CPM provides the best in equipment, dies, parts and services which together represent the Lowest operating cost solution to our customers. Innovative engineering and design have been combined with the latest manufacturing technology. CPM pellet Crumblers are high-capacity (ranging from 10 to 40 t/h), high- efficiency machines. The rugged design and user-friendly features ensure many years of continuous, reliable Operation. CPM pellet crumblers are available in a variety of capacities constructed to match the output requirements of your process. Crumblers are built to operate 24 hours a day in tough running conditions.

CPM - Model Champion Series - Hammer Mills

The CPM Champion hammer mills have been designed extremely heavy duty to perform under the most demanding conditions. The Characteristic tear circle design in combination with the high tip speed makes the CPM Champion a true winner.Since many years, hammer mills are used in various industries and nowadays often play an important role in production facilities. The most hammer mill grinders are used in the animal feed industry, but also in other industries, hammer mills are found.

CPM - Liquid Addition for Pelleting Systems

More than twenty years of experience brought us up to the state of the art next generation coater for post pelleting applications like fat and enzymes. Guarantees high quality equal sprayed dust free pellets with high fat content. CPM Liquid Addition: The first step to quality improvement is spraying fat at the pellets after they left the pellet mill. Spraying fat allows a higher proportion of fat to be included, permitting the use of lower cost raw materials, while maintaining pellet quality. Generally there are two mayor places in the pelleting lines were it is relatively easy to dose accurately fat. This is or directly on the pellet mill die, or in a coater after the cooled pellets left the sifter.

CPM ROSKAMP - Roller Mill

The CPM ROSKAMP Roller Mill has established a strong market position as a machine for the production of mash feed with an extraordinary good structure. The rugged construction guarantees maximum performance around the clock.

Pellet Mills

Innovative engineering and design have been combined with the latest manufacturing technology to provide the highest quality pellet mills in the world with the best production levels ever achieved, along with excellent pellet quality. More and more industries are discovering the advantages of pelleting. The application possibilities of pellet mills in today`s process industries are virtually endless. In addition to animal feeds, other materials being pelleted by CPM customers include detergents, polyethylene, carbon, insecticides, RDF, sawdust, asbestos, pharmaceuticals, urea, polyesters, coal dust, latex, coffee, organic fertiliser, polyesters, potash, charcoal, zinc oxide, herbicides, to name just a few.

Crackers / Crumblers / Crushers

The Roskamp Crumbler is used in the Feed industry and is easily adapted to full-automation. Load-centering bearing supports and unique bearing slides assure accurate, consistent production. Roll corrugation and speed differential ratios are available to match any operating condition. The Roskamp Crumbler is designed for the most demanding applications.

Hammer Mills

Since many years, hammermills are used in various industries and nowadays often play an important role in production facilities. The most hammermill grinders are used in the animal feed industry, but also in other industries like Biomass, hammermills are found. Grinding of products like saw dust and wood chips for fuel purpose are nowadays very common. Grinding of tough, fibrous products require stronger and more heavy duty machinery. For grinding pet foods and aquatic feeds also other demands apply. The ability of fine grinding at high capacity requires hammermill features like large screen area, high tip speeds and a small clearance between hammer and screen. The hammermills of the Champion product line have been designed to suit each specific grinding requirement.

Pellet Mills

As the world`s largest manufacturer of pellet mills, CPM has led the way in developing specialised pellet mills and dies to make pelleting both practical and economical while enhancing product value and manageability in the Feed, Oilseed, Biomass and other industries.