- Home

- Companies

- Advanced Micro Instruments, Inc. (AMI)

- Products

- AMI - Model 70 - Percent Oxygen ...

AMI - Model 70 -Percent Oxygen Analyzer

The MODEL 70 is a Percent Oxygen Analyzer that is a perfect choice for accurately measuring in a NON- FLAMMABLE gas stream. The MODEL 70 is supplied in a compact, panel mount package and suitable for use in general purpose environments. The unique zirconium oxide sensor technology produces an incredibly accurate and stable reading over a wide O2 measurement and temperature range. The sensor has an unprecedented 10-year life expectancy, requiring only annual calibrations.

Full of Standard Features

The MODEL 70 Percent Oxygen Panel Mount Analyzer comes standard with advanced features, including 4-user selectable analog output ranges, dual independent alarms, comprehensive alarm logic (fail safe or non-fail safe, latching or non-latching and independent alarm delays), alarm bypass, and 3 levels of security settings. Automatic data logging provides detailed time-stamped records of O2 measurement, temperature, supply voltage and power brown-out history.

Zirconium Oxide Sensor Technology

AMI’s zirconium oxide sensors are extremely accurate and stable, have a 10-year life expectancy and are unaffected by barometric pressure fluctuations or rapidly changing temperatures from 0-120°F. Recommended calibrations are 1-2 times per year in the 0-25% oxygen range.

Exceptional Value

The MODEL 70 is the perfect choice for accurately measuring percent levels of oxygen in either inert background gases or enriched oxygen gas streams up to 95% O2. The MODEL 70 is a maintenance-free, compact analyzer loaded with advanced features at an exceptional price.

ALARMS

2 fully adjustable concentration alarms with configurable Alarm logic and Relay Contacts, featuring:

- Alarm Bypass

- Latching/Non-latching

- Alarm Delays

- Failsafe/Non-failsafe

- Trigger Above or Below Setpoint

- Open or Close on Alarm

ANALOG OUTPUTS

4 − 20mA or 0 - 1 VDC isolated output signals and Modbus bi-directional RS485 communication

COMMAND CENTER

Software that works across AMI’s Analyzers and gives users access to advanced functions:

- Calibration Details

- Alarm Configurations

- Data Logger with Adjustable Interval Setting

ACCESSORIES

- COMMAND CENTER

- Zirconium Oxide Sensors (note: sensor is not field replaceable)

The AMI model 70R1 is the ideal solution for measuring oxygen in non-flammable gases in a general purpose environment. In a very small size, and at low cost, it provides a complete electronic package with a full set of features together with a zirconium oxide sensor that has an expected ten year life, with virtually no calibration required.

- Percent oxygen in non-flammable samples

- General purpose panel mount analyzer

- Extremely stable, long-life sensor

- Orifice controlled flow

- Virtually unaffected by temperature changes

- Virtually unaffected by barometric pressure changes

- Virtually unaffected by humidity changes

- Virtually unaffected by flow rate changes

- Calibration interval 6 months

- Very small size

- Complete electronics and software package

- Datalog

- ModBus connectivity

- Two relay contacts for alarms

- Isolated 4-20mA output

- Low cost

Traditional electrochemical oxygen analyzers suffer from poor stability, requiring monthly calibration and frequent sensor replacement, and they suffer from sensitivity to both temperature changes and barometric pressure changes. Their reading can change by as much as 10% when a weather change occurs. The AMI model 70R1 suffers from none of these issues. It has been tested over a temperature range of 0°F to 120°F.

Its sensor is unaffected by flow rate changes over the range of 0.1 to 5 SCFH, and as a result AMI is able to use an orifice to control the flow.

The analyzer is built around a modified version of the same electronic architecture used in most of AMI’s advanced analyzers. Two microprocessors working together provide a vast amount of functionality, with the industry’s most intuitive front panel controls married to the most complete PC user interface. For advanced users, ModBus RTU over RS-485 is also provided as standard.

Alarm set points, the range over which the 4-20mA output is spanned, and calibration are controlled by press buttons. These can be disabled via the user interface if desired for greater security.

Complete control over the analyzer’s operation, and access to its many diagnostic features, are available via the AMI software running on a PC, connected via a standard USB cable.

Diagnostic features include a datalog – ten days plus of complete records of the oxygen reading; calibration history for the previous five calibrations; brown out and power up history, including memory errors if any; ambient temperature, sensor heater voltage and calibration factors; and for advanced users, the ability to “tweak” the linearity to match reference gases.

Optional ranges of 0-50% and 0-95% available.

- Percent oxygen measurement from 0.00% to 25% in non-flammable gases.

- 50% or 95% versions available.

- Long-life high-stability zirconium oxide sensor.

- Expected sensor life of over ten years.

- Virtually no sensitivity to barometric pressure or ambient temperature.

- Virtually no sensitivity to humidity changes.

- No support gases required.

- Built-in orifice for flow control over a wide input pressure range.

- Virtually unaffected by sample flow rate changes between 0.1 – 5 SCFH.

- Panel mount.

- Compact size.

- 4 user selectable output ranges.

- 3 ½ digit LCD.

- 2 fully adjustable oxygen concentration alarms• RFI protected.

- Isolated 4-20mA. analog output signal (may be set to 0-1VDC if required).

- USB connection for AMI User interface software.

- RS485 connection for ModBus communication.

- Power requirements: 10-28VDC

- Low original cost and virtually maintenance free over its entire life.

- Area Classification: Designed to meet General Purpose requirements.

- 2 year warranty for analyzer and sensor, parts and labor.

- 4 user selectable outputs: 0-1%, 0-5%, 0-10% and 0-25% Optional ranges: 0-50% or 0-95%. The selection of an output range simultaneously controls the two alarms, the analog output and the datalogger so that all 4 functions operate on the same range.

- Digital display: 3 ½ digit LCD. Reads full scale from 0.00% to 25.0% independently of output range selection.

- Alarms: 2 fully adjustable oxygen concentration alarms. Dry contacts 3A. @24VDC/230VAC.

- Analog output signals: Isolated 4-20mA or 0-1VDC. Represents the output range selected: 0-1%,0-5%, 0-10% and 25%.

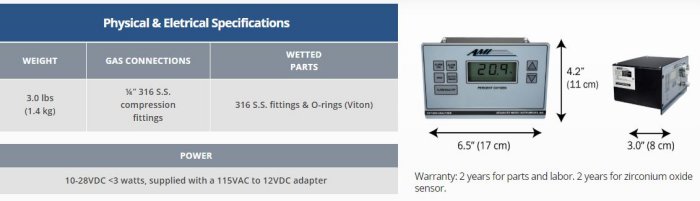

- Power requirements: 10-28VDC

- Minimum detection: 0.05% of oxygen.

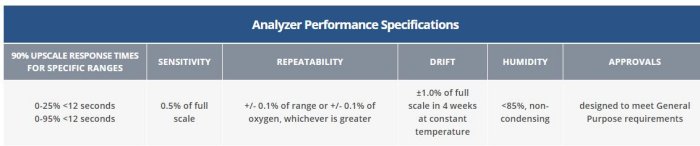

- Repeatability: +/- 0.1% of range or +/- 0.1% of oxygen, whichever is greater.

- Operating temperature range: 0 to 130˚ F.

- Diurnal temperature specification:< +/- 2 % of scale over temperature range.

- Response times: 90% full scale response times for specified range:0-25%

- Long life zirconium oxide sensor: 10 year life expectancy.

- Area Classification: Designed to meet General Purpose requirements.

- Inlet gas pressure: 1.0 to 30psig.

- Gas connections: ¼” 316 S.S. compression fittings.

- Wetted parts: 316 S.S. fittings and critical orifice,anodized aluminum cellblock.

- Unaffected by changes in flow rate from 0.1 to 5.0 SCFH.

- Mounting: panel mount.

- Dimensions: 6.5”W x 4.2”H x 3.0”D .

- Weight: 3 lbs.