- Home

- Companies

- Aqua|Still B.V.

- Products

- AQUA|FLEX - Model 100 - Pilot Systems

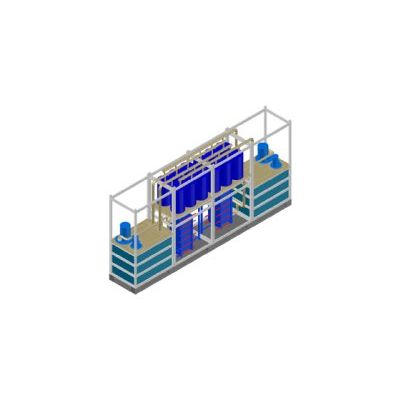

AQUA|FLEX - Model 100 -Pilot Systems

The AQUA|FLEX 100 is a standardized installation which can be used for demonstration purposes at customers during a few months. It’s a flexible unit which can be used for several purposes with heat and cooling on site. Production of distillate water or concentrating beverages and brines are a few applications. It’s shows the reliability of the modules during longer times under daily process conditions. Production capacity for this unit ranges from 200 ltr/hr up to 1000 lt/hr which depends on temperature profiles and fluid properties of the customer.

Multiple Configurations

For large commercial plants we use standard building blocks, the same used for the AQUA|FLEX 100 and AQUA|FLEX 150R units. By placing several units next to each other, this approach provides great flexibility, reliability, and variability in the production capacity for the customer. The system can be installed quickly and expanded to suit customers’ needs. For specialized full-scale industrial configurations, please contact us to discuss the possibilities in detail.

ENGINEERING

Feed/bleed block an distillate production block

For the feed/bleed block and the distillate production block we use a standardized unit consisting of two tanks; a circulation pump; a discharge pump; the transmitter for flow, temperature, and pressure measurements; and an E-cabinet.

Heat input block and heat removal block

These blocks consist of two levels, whereby the lower level provides or discharges heat by means of a heat exchanger and the upper level holds six membrane modules. Piping trays are integrated on the skid for feed and discharging of the modules.

Heat regeneration block

This block can be added to the above four blocks when there is a need for heat regeneration. An extra heat exchanger regenerates the heat that is lost due to water evaporation in the membrane modules. The heat exchanger is installed on the first level and extra optional membrane modules can be installed on the second level of the pallet.