- Home

- Companies

- Aqua|Still B.V.

- Products

Aqua|Still B.V. products

Pilot Systems

AQUA|FLEX - Pilot Systems

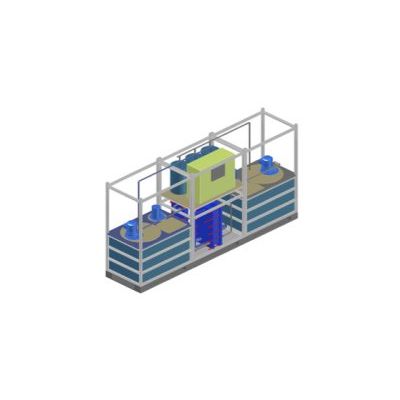

This installation is a pilot system specially designed for continuous operation with aggressive fluids such as acids and brine solutions on site. Remote control and data-logging are standard. The unit consists of three standard-sized pallets which contain the brine circulation loop, the distillate circulation loop, and the core of the unit with membrane modules and several heat exchangers for regeneration, heating, and cooling. The capacity for normal seawater with a temperature range of 20-85 °C results in a distillate production of approximately 200 l/hour

AQUA|FLEX - Pilot Systems

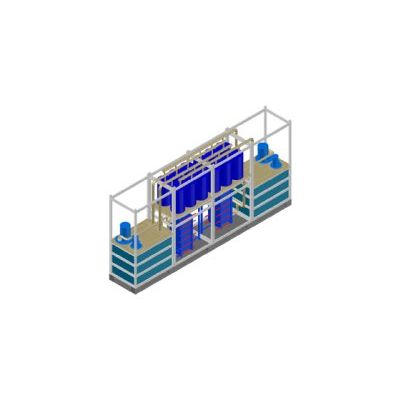

The AQUA|FLEX 100 is a standardized installation which can be used for demonstration purposes at customers during a few months. It’s a flexible unit which can be used for several purposes with heat and cooling on site. Production of distillate water or concentrating beverages and brines are a few applications. It’s shows the reliability of the modules during longer times under daily process conditions. Production capacity for this unit ranges from 200 ltr/hr up to 1000 lt/hr which depends on temperature profiles and fluid properties of the customer.

AQUA|FLEX - Pilot Systems

The AQUA|FLEX 150R is an extended version of the AQUA|FLEX 100. Waste heat is recovered by using an extra heat exchanger which results in a more energy efficient system. This system is designed for medium to large scale applications. Extra modules can be added to enlarge the total capacity of this system.

Modules

The main two pillars in the patented design of the modules where efficiency and reliability. With this mind only the best and most advanced materials are selected from our suppliers to make sure AQUA|STILL modules are the standard in the membrane distillation industry. Watertight modules are guaranteed by using a very advanced production method with a minimum number of production steps. Archimedes spiral shaped flow channels provide a 100% counter current flow pattern to optimize the driving force for the process.

AQUA|STILL - Lab Units

AQUA|STILL’s lab units can be used for simple sample testing and gives the first insight in technical feasibility of the membrane distillation process.

Membrane Distillation

Direct Contact Membrane Distillation

Direct Contact Membrane Distillation is the most straightforward form of membrane distillation, consisting of the membrane modules and the respective heat exchangers.

Air Gap Membrane Distillation

Air Gap Membrane Distillation is the most energy-efficient of our process configurations. This makes it ideal for solar/green energy applications without limiting the module’s output capabilities. AQUA|STILL currently has the single largest AGMD modules in the world, at over 24 m2 meters and with measured performance ratios surpassing 10.

Liquid Gap Membrane Distillation

Liquid Gap Membrane Distillation (LGMD) is one of the more recently developed process configurations, providing extremely pure water at a lower yield compared to AGMD.