Input Voltage: +18 to 32 VDC)

Power Consumption: ≤ 2 W

Outputs:

4-20ma

RS-485 (Modbus)

Relays

Sensor:

Ultrasonic Acoustic

Electromagnetic

Magnetic

The DSES detector is designed to detect and record the passing of Pipeline Inspection Gauge (hereinafter referred to as the PIG).

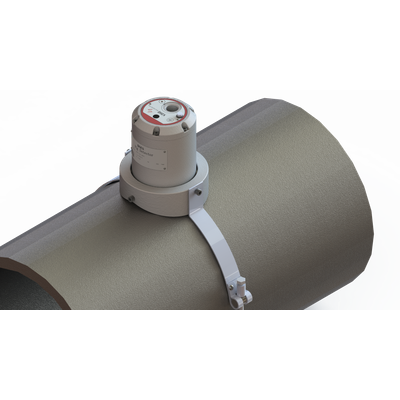

The DSES detects PIG passages by processing signals from 3 different sensor channels and transmitting data to the automatic process control system. According to the principle of operation, DSES is a contact device and intended for installation directly on the surface of the oil and gas pipeline. The detector is non-intrusively mounted on a straight pipe section

with a mounting clamp.

The detector has 3 measuring channels:

Acoustic noise in the frequency range of 100-250 kHz created by a moving PIG is captured using a metal hub pressed against the surface of the pipe and a piezoelectric sensor rigidly mounted on the inner side of the hub.

The electromagnetic signal of a low-frequency transmitter, optionally mounted on PIGs, with a frequency of 22 Hz is received by an antenna built into the detector.

Fluctuations of a constant magnetic field caused by the movement of permanent magnets, also optionally mounted on PIGs, are detected by the same built-in antenna as a signal with frequencies from fractions to units of Hz.

A PIG passage indication occurs when thresholds are exceeded by at least two channels – acoustic (permanent) and electromagnetic OR magnetic.

The device can also be configured to activate PIG passage when one channel threshold is exceeded. The levels of threshold values are set by setting a number of parameters for each channel separately using factory configuration software.

Input Voltage: +18 to 32 VDC)

Power Consumption: ≤ 2 W

Outputs:

4-20ma

RS-485 (Modbus)

Relays

Sensor:

Ultrasonic Acoustic

Electromagnetic

Magnetic

LED Indication: Green, Red, Yellow

IP Rating: IP66/68

Explosion Proof Rating: Ex db IIC T4 Gb

Relative Humidity: Up to 95% (non-condensing)

Operating Temperature: -60C to +85C

Pipe Thickness: 2-25 mm

Pipe Diameter: 300-2500 mm

Pipe Material: All types of steel alloys

Operating Mode: Real time measurement

Speed of Moving PIG: 0,1-10 m/s

Detection Direction: Bidirectional

Flow Conditions: Oil, Gas, Water, Multiphase

Repeatability: <1%

Mounting: Non-Intrusive via mounting bracket

Enclosure Material: Aluminum/SS316

Weight: 2.5 kg (Al)/ 5.0 (SS316)

Warranty: 2 Years