5 products found

ESP Asset Integrity products

Acoustic Sand Detectors

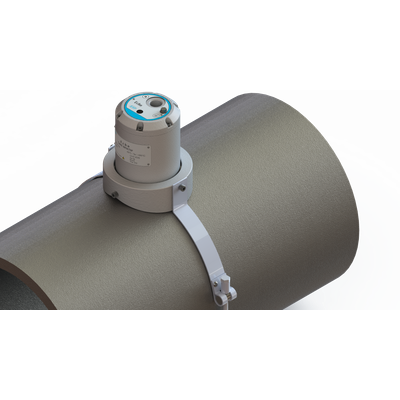

ESP Asset Integrity - Model ECHO - Acoustic Sand Detector for Pipeline Monitoring

The ECHO Acoustic Sand Detector is a sophisticated tool designed to enhance the integrity and safety of subsea and topside assets by monitoring solid particles in single and multiphase flowing operations. Utilizing ultrasonic technology, the device listens for the acoustic noise generated by sand and other particulates as they impact pipeline walls, alerting operators when these exceed safe concentrations. This triggers protective actions to safeguard critical infrastructure and optimize production. Employing digital signal processing algorithms, ECHO provides real-time data and can seamlessly integrate into existing systems through digital, analog, or wireless interfaces. Known for its enhanced acoustic sensitivity and reliability, this detector is cost-effective with minimal maintenance and is adaptable for diverse climates, from polar to tropical regions. Available in both onshore and subsea versions, the ECHO detector is precision-engineered from premium materials like 316 stainless steel or aluminum, ensuring long-term durability and performance in extreme conditions.

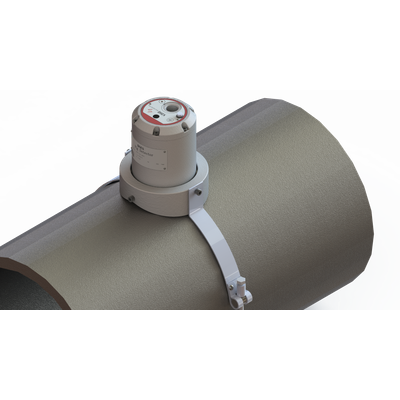

ESP Asset Integrity - Model ECHO-UW - Echo Acoustic Sand Detector

The Echo Acoustic Sand Detector is an advanced industrial tool that uses ultrasonic technology to monitor the presence of solid particles in gas and fluid flow within pipelines. This device detects acoustic noise generated when particles such as sand collide with pipeline walls, thereby alerting operators when particle concentrations reach minimum acceptable levels. As a smart instrument, it leverages digital signal processing algorithms to provide real-time data to operators. Output signals are compatible with SIIS Level 2 and Level 3 communication protocols for seamless integration with control systems. Designed as a non-intrusive solution, it can be tailored to existing or new pipeline systems and is recommended for use alongside erosion-corrosion detectors to prolong the lifespan of pipelines by mitigating sand-related erosion. The device features robust design specifications, utilizes materials such as UNS S31803/2205 Duplex SS or Titanium, and operates effectively across a wide range of environmental conditions, ensuring reliability over a 30-year design life.Erosion Corrosion Sensors

ESP Asset Integrity - Model Echo-EC - Erosion-Corrosion Detector

The Echo-EC Erosion-Corrosion Detector by ESP Safety is engineered to address the pervasive issue of erosion-corrosion in oil and gas production systems, which often experience increased wear due to the presence of sand and high production velocities. This device employs multiple acoustic sensors utilizing a pulse-echo method to measure pipe wall thickness, providing real-time data transmission through Modbus RS-485 protocol. The system includes 4 to 32 sensors, supporting advanced signal processing algorithms for reliable, high-resolution monitoring. Users benefit by optimizing corrosion inhibitor use and determining pipeline lifespan, crucial for maintenance planning. The non-intrusive design facilitates integration into both new and existing infrastructures, and it's recommended to be paired with a sand detector to further mitigate sand intrusion-related corrosion. Operating within a broad temperature range and accommodating various metal alloys, it represents a sophisticated solution for maintaining pipeline integrity.

ESP Asset Integrity - Model ECHO EC-UW - Erosion-Corrosion Detector

The Echo-EC is an advanced erosion-corrosion detector that addresses significant industry challenges in oil and gas production systems. Utilizing acoustic sensors, the device employs a pulse-echo method to assess wall thickness, with configurations ranging from four to thirty-two sensors. These sensors provide real-time data, enabling integration with existing monitoring systems through SIIS Level 2 or Level 3 communication protocols. The detector's digital signal processing enhances data accuracy and resolution, assisting operators in preventive maintenance planning, optimization of corrosion inhibitors, pipeline lifespan analysis, and weld/HAZ monitoring. This non-intrusive instrument facilitates seamless installation in new or existing setups, allowing for improved corrosion management when used in conjunction with sand detectors to mitigate erosion. Its robust construction includes materials like titanium and duplex stainless steel, capable of enduring extreme operational conditions with a design life extending to 30 years.Acoustic PIG Detectors

ESP Asset Integrity - Model DSES - Pipeline Inspection Gauge Detector

The DSES detector is engineered to effectively detect and record the passage of Pipeline Inspection Gauges (PIGs) on oil and gas pipelines. It is designed as a contact device for direct installation on the pipeline surface using a non-intrusive mounting clamp. This system processes signals from three sensor channels: an ultrasonic acoustic channel, an electromagnetic channel, and a magnetic channel. The ultrasonic acoustic channel utilizes a metal hub and piezoelectric sensor to capture noise in the 100-250 kHz frequency range. The electromagnetic channel receives signals via an antenna from a 22Hz low-frequency transmitter on PIGs, while the magnetic channel detects fluctuations in the magnetic field caused by permanent magnets. The system requires at least two channel thresholds to be exceeded, offering flexibility in configuration to ensure accurate indication of PIG passages. Operating efficiently under various conditions, DSES supports real-time measurements and is designed to withstand extreme temperatures and environmental challenges, offering reliability for monitoring operations in oil, gas, and water flows.