- Home

- Companies

- Mahr Metering Systems GmbH

- Products

- Mahr MarSpin - Planetary Spinning Pumps

Mahr MarSpin - Planetary Spinning Pumps

Planetary spinning pumps – representing the heart of a spinning plant. They are used in large quantities. Tight production tolerances of the pumps, reliability and long life time are the key words for a high quality yarn and customer satisfaction. Feinpruef spinning pumps of Mahr Metering Systems do guarantee to withstand toughest process conditions to finally spin and deliver a first class quality yarn to the winder.

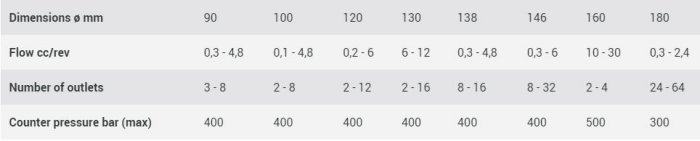

The special feature of planetary spinning pumps is the dosing of a material flow into up to 64 equal individual streams. These pumps are not only used for production of many different synthetic fibre and yarn, of that, for example, micro fibre textiles, tights, spandex, protective clothing and even astronautic overalls will be made. Planetary spinning pumps are also used for applications of dosing glue & adhesives and almost all kind of fluids.

The pump drive connection is available in following types:

- shaft type

- plug type

Gear pump with motor

- Base plate with mounting block

- Coupling

- curved tooth coupling

- cardan shafts

- all-steel coupling

- magnetic coupling

- Motor

- asynchronous gear motor

- servomotor / servo gear motor

- synchronous gear motor

The drive units are designed according to the operating conditions.

Coating technologies take a significant key position in the development of new products. The various coating technologies enlarge the application possibilities of the base materials. Furthermore, a coating reduces friction, wear and corrosion. In principle, all named materials can be coated depending on the specification.

Diamond-Like Carbon (DLC) improves the properties:

- high surface hardness

- high wear protection

- smaller coefficient of friction

- better corrosion reduction to aggressive media

- higher chemical resistance / stability

- non-stick effect (reduced adhesion of polymers and other materials)

- high temperature firmness to 250°C

- excellent accuracy to size (no change of the high discharge accuracies)

- high economic efficiency through longer endurance and improvement of technological properties

- biocompatible, allows the use in the food industry and in the medical field

Sealing systems for the gear pumps

- stuffing box seal

- rotary shaft seal

- labyrinth seal

- mechanical seal

- magnetic coupling

Atex Directive 2014/34/EU

A version according to the Atex directive is available for the pump as well as for the drive.

Heating or cooling for the gear pumps Heating or cooling can be provided electrically as well as by the thermal fluid.