Dustmaster Enviro Systems, a division of Mixer Systems, Inc.

- Home

- Companies

- Dustmaster Enviro Systems, a division ...

- Products

- Dustmaster - Planetary Style Mixer

Dustmaster - Planetary Style Mixer

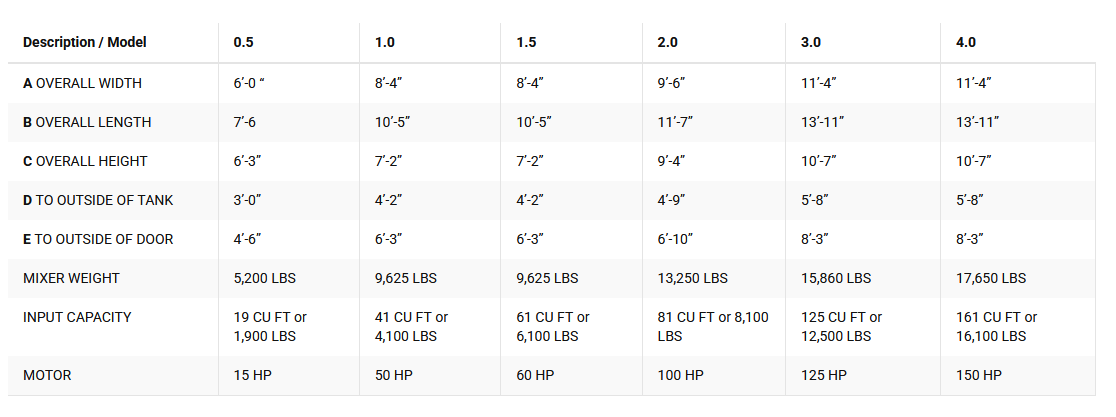

High-performing mixer for a broad range of materials. The DustMASTER planetary style mixer is a fast, efficient machine ideally suited to a wide variety of materials including fly ash, baghouse dust, foundry sands, powdered metals, cement kiln dust and dry chemicals. Counter-current mixing action achieves a homogeneous mix in as little as 30 seconds, as material is quickly mixed from top to bottom and moves opposite the direction of the paddles for thorough blending. Long-wearing and high-performing components reduce maintenance and prolong life. Capacities from .5 to 4 cubic-yards are available.

Most popular related searches

non-hazardous medical waste

cement industry dust

medical waste incineration

flow control valve

non-hazardous waste

baghouse dust

steel tank

hazardous medical waste

cement industry

kiln dust

Mixer Tank

- 3/16” thick steel tank wall

- 3/8” thick steel tank floor

- Tank is welded to structural steel channel frame

- Channel frame has lifting lugs for unloading and handling of mixer

Liners

- Abrasion resistant steel floor liners

- Abrasion resistant steel wall liners

- All are replaceable, bolted segments

Wall Scrapers and Paddles

- Formed steel arms with replaceable rubber wear guards

- Inside and outside replaceable cast Ni-Hard scrapers

- Cast Ni-Hard, or rubber, replaceable floor paddles

Discharge Door

- Steel door pivots on self-lubricated sleeve bearing

- Up to four (4) doors at 90-degree increments

- Air cylinder operated linkage with hand operated valve

- Flow control valve for speed adjustment

- Air line lubricator and moisture trap

Drive Train

- Planetary gearbox

- Modular type with heavy-duty swing bearing and hardened gears

- Belt-driven from reducer to motor on all other models

- Removable from top of mixer

- TEFC 230/460 volt, 3 phase, 60 hertz motor

Lubrication System

- Static oil system on Models 0.5, 1.0 and 1.5

- Oil lube system with pump, flow switch and reservoir on Models 2.0, 3.0 and 4.0

Mixer Cover

- Steel top cover lid

- Hinged access doors on top of mixer

- One door will have a hinged inspection door

- Doors are gasketed for dust and water containment

- Doors include ‘doors closed’ interlock switches

Paint

- One color, high grade machinery enamel

- Baghouse dust residue

- Bottom ash

- Calcium oxide

- Cupola dust

- Heavy metals and iron oxides

- Fly ash

- Foundry sand

- Hazardous and non-hazardous wastes

- Medical incinerator waste

- Municipal incinerator waste

- Low-grade nuclear waste

- Pyrites

- Shot blast

- Economizer ash

- Waste to energy