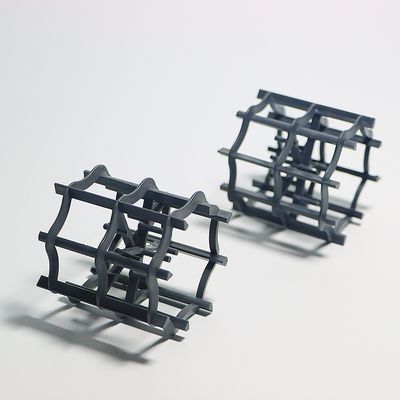

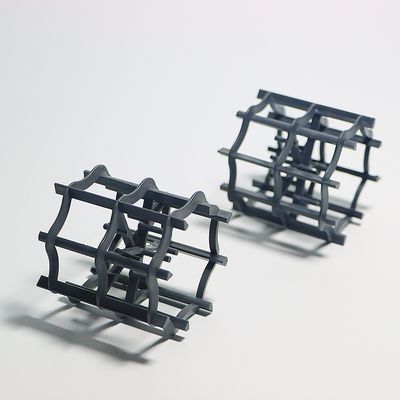

Plastic VSP Ring also called Mella Ring. Its structure is very similar with Nor-pak. External Rid &protruding Drip fins’ cross will promote gas & liquid evenly distribution and large size pore’s structure will avoid of Tower Packing’s internal plugging.Eight Arc Horizonal Bar that bends towards inside ensures liquid un-continuely renew. Meanwhile, Vertical triangle straight rod connected two Arc Bar largely speed up air-liquid exchanging speed.Owing to its rational symmetry, excellent inner structure, large free space, compared with plastic pall ring, its flux effiency is increase 15-30% , its pressure drop is reduce 20-30%.Therefore, Plastic VSP Ring is used in water treatment, exhaust-gas cleaning and in all processes where the interface between gas and liquid plays a decisive role.