- Home

- Companies

- Hebei Lianda Filter Equipment Co., Ltd.

- Products

- Lianda Filter - Pleated wire mesh ...

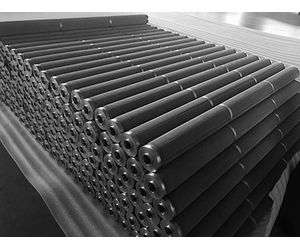

Lianda Filter - Pleated wire mesh filter cartridge

Pleated wire mesh filter cartridges are made of pleated wire cloth filter media. Multi-layers of wire mesh are spot welded and then pleated and pressed. The pleats are welded by two ends to form the cartridge body. Then the hardware (end fitting, adapter) is welded with the body. The filtration layer is often wrapped in the middle of inner and outer protection layer. Extra transition layer may be added beneath the filtration layer for protection if it is supper fine and subject to deformation and damage. Inner support tube and outer protection sleeve are optional depending on the pressure condition of working and backwashing.

Comparing to ordinary cylindrical wire mesh filter elements, the pleated wire mesh filter cartridges can achieve:

- larger effective filtration area

- higher flow rate

- excellent dirty holding capacity

- robust structure for better life span

The pleated wire mesh filter cartridges are good substitute for non-metallic filter cartridge as they can withstand higher temperature & pressure and can be backwashed and reusable, in applications of steam, hot air and liquid filtration.

For in-depth filtration requirement, the filtration layer can change into sintered metal fiber felt, as the felt is also suitable for pleating.

Customized sintered wire mesh laminates can also be made into pleated filter cartridges. The pleated sintered mesh filter cartridges eliminate the gaps between ordinary pleated mesh filter, thus avoid the impurity clogging in the gaps and make the filter cartridge more easy and ready to be cleaned.

The hardware / end fitting material can be different with the wire mesh.

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are the among the standard material for pleated wire mesh filter cartridges.

Other exotic materials are also available as request, such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc.