- Home

- Companies

- Particle Measuring Systems (PMS)

- Products

- PMS - Model Airnet - II - 4-Channel ...

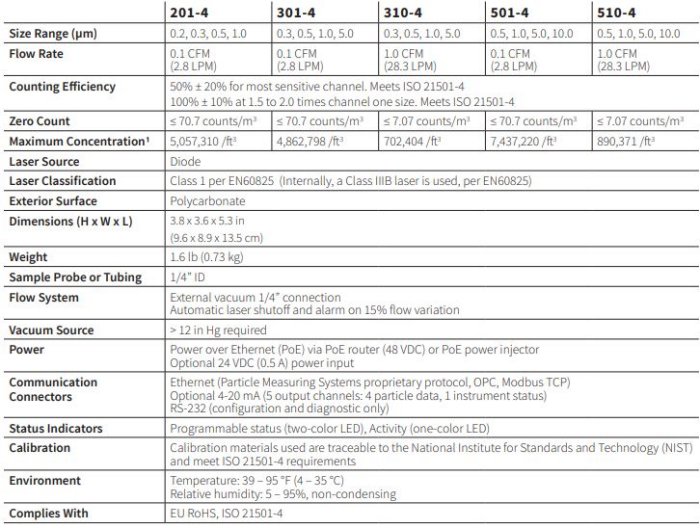

PMS - Model Airnet - II -4-Channel Continuous Particle Sensor

The Airnet II is ideal for remote continuous particle monitoring as a component of a Facility Monitoring System. It meets the specifications of ISO 21501-4 and EU GMP Annex 1 to measure the size and number of particles suspended in the air for real-time monitoring of defect-causing particles.

The Airnet II Particle Sensor provides unparalleled performance with data transmission capabilities for remote monitoring. Versatile power options combined with an ultra-small footprint make the Airnet II Particle Sensor easy to install right where you need it.

The unit can be configured to accept distributed power from an in-house system or power over ethernet (PoE). Data integrity is maintained through the use of a data queue feature that continues to gather data even if communication is lost. To ensure proper flow conditions and vacuum system operation, these units incorporate a Dynamic Flow Sensing system that will alarm with a 15% change in flow conditions.

Particle Measuring Systems engineers, manufactures, installs, calibrates, repairs, and maintains the Airnet® II Continuous Particle Sensor.

- 4 channels

- 0.2, 0.3, 0.5, 1.0, 5.0, and 10.0 μm size range

- 0.1 or 1.0 CFM flow rate

- Interfaces with object linking and embedding (OLE) for process control (OPC) communications, Modbus communications and optional 4-20 mA output

- Chemical-resistant polycarbonate (PC) enclosure

- Low sample point cost

- Proven technology provides reliable and accurate data

- Allows for immediate reaction to particle contamination events

- A low-cost solution for multipoint monitoring

- Interfaces with Facility Net, Pharmaceutical Net and FacilityPro Software for comprehensive management of cleanroom conditions

- A small footprint and flexible mounting options make it easy to install in cleanrooms and mini-environments

- A laser diode (LD) drastically reduces the need for maintenance and extends product lifecycle

- Automatic laser shutdown reduces laser failures

- Real-time monitoring of defect-causing particles

- Easy to clean/wipe down; designed to minimize particle traps

- Power over Ethernet (PoE) simplifies installations

- OPC or Modbus TCP communications easily utilized

- Optional 24 VDC input / 4-20 mA output configurations available

- Cleanroom monitoring

- Dedicated monitoring of critical locations

- Trend analysis

- Statistical process control

- Multi-location monitoring

- 4 channels

- 0.2, 0.3, 0.5, 1.0, 5.0, and 10.0 μm size range

- 0.1 or 1.0 CFM flow rate

- Interfaces with object linking and embedding (OLE) for process control (OPC) communications, Modbus communications and optional 4-20 mA output

- Chemical-resistant polycarbonate (PC) enclosure

- Low sample point cost

- Small enough for use in remote locations

- ISO 21501-4 and EU GMP Annex 1 compliant

- Proven technology provides reliable and accurate data

- Allows for immediate reaction to particle contamination events

- A low-cost solution for multipoint monitoring

- Interfaces with Facility Net, Pharmaceutical Net and FacilityPro Software for comprehensive management of cleanroom conditions

- A small footprint and flexible mounting options make it easy to install in cleanrooms and mini-environments

- A laser diode (LD) drastically reduces the need for maintenance and extends product lifecycle

- Automatic laser shutdown reduces laser failures

- Data queue maintains data integrity when communication is lost

- Optional 4-20 mA output for integration with existing systems to help you understand your environment and communicate with other systems

- Cleanroom monitoring

- Dedicated monitoring of critical locations

- Trend analysis

- Statistical process control

- Multi-location monitoring

- Isolator monitoring