- Home

- Companies

- Zhejiang BW Industry Co., Ltd

- Products

- BW-Industry - Model 450G - Polyether ...

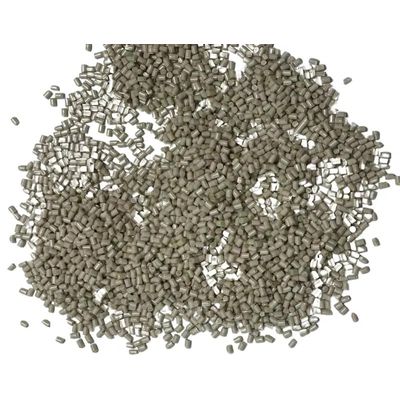

BW-Industry - Model 450G -Polyether Ether Ketone (PEEK) Granules

Peek 450 Series High performance thermoplastic material, unreinforced PolyEtherEtherKetone (PEEK), semi crystalline, granules for injection moulding and extrusion, standard flow, FDA food contact compliant, colour natural/beige and black.

Main products: 450 Unfilled Powder PEEK,450 Unfilled Granule PEEK,450 Glass Fiber Filled PEEK,450 Carbon Fiber-Filled PEEK,450 Wear-Resistant Grade PEEK

In addressing complex engineering challenges, innovative solutions that replace metal with plastic are increasingly becoming reality. PEEK, as a premier engineering plastic, stands out as the material of choice due to its exceptional performance, marking a significant milestone in technological advancement.

In addressing complex engineering challenges, innovative solutions that replace metal with plastic are increasingly becoming reality. PEEK, as a premier engineering plastic, stands out as the material of choice due to its exceptional performance, marking a significant milestone in technological advancement.

PEEK 450P Material Description

PEEK 450P is a high-performance thermoplastic material, an unreinforced PolyEtherEtherKetone (PEEK) coarse powder suitable for extrusion compounding, with standard flow and FDA food contact compliance.

Recommended Processing Conditions

Drying Temperature / Time: 150°C / 3h or 120°C / 5h (residual moisture <0.02%)

Processing Temperature: 380-400°C

The Difference Between Tensile Modulus and Flexural Modulus and Its Impact on Product Performance

Tensile modulus and flexural modulus describe the rigidity of the material under tensile and bending stresses, respectively. PEEK 450P`s tensile modulus is 4.0 GPa, and its flexural modulus is 3.8 GPa, indicating slightly higher rigidity in tensile state. This difference suggests that PEEK 450P may be slightly more flexible when subjected to bending forces, which is particularly important for applications requiring certain bending performance without breaking.

How Does the Change in Melt Viscosity at Different Temperatures Affect the Processability of PEEK 450P?

Melt viscosity is an indicator of material flowability, especially important during processing. PEEK 450P has a melt viscosity of 350 Pa.s at 400°C, showing good flowability. Generally, an increase in temperature tends to decrease melt viscosity, thereby increasing material flowability. For PEEK 450P, appropriately adjusting the processing temperature can optimize its flowability to meet different processing needs, such as injection molding or extrusion, thereby improving product quality and reducing defects.

How Does the Relationship Between the Glass Transition Temperature (Tg) and Melting Point Affect Its Thermal Performance?

Tg and melting point are two key parameters affecting the thermal performance of thermoplastic materials. PEEK 450P`s Tg ranges from 143°C to 150°C, and its melting point is 343°C. This indicates that below Tg, PEEK 450P behaves in a glassy state, showing higher rigidity and stability; as temperature rises above Tg and before reaching the melting point, the material becomes softer and more pliable but retains its shape; at the melting point, the material enters a flow state and can be molded using various techniques. This wide temperature range offers great application flexibility, allowing PEEK 450P to maintain excellent mechanical and thermal performance across a broad temperature range.

How to Optimize PEEK 450P`s Mechanical Properties by Adjusting Processing Conditions?

Optimizing PEEK 450P`s mechanical properties can be achieved by adjusting drying time and temperature, processing temperature, and cooling rate. Firstly, ensuring the material is thoroughly dried before processing (recommended 150°C/3h or 120°C/5h) to eliminate residual moisture, as moisture can affect material flowability and final mechanical properties. Secondly, precise control of the processing temperature (380-400°C) ensures proper flowability of the material in its molten state, facilitating molding and reducing stress concentrations. Lastly, an appropriate cooling rate can reduce residual stress, preventing warping and shrinkage, thereby improving product dimensional stability and mechanical properties.

How Does PEEK 450P Perform Differently in Various Processing Techniques, Such as Injection Molding and Extrusion?

The performance differences of PEEK 450P in injection molding and extrusion primarily lie in its flowability and cooling rate management. During injection molding, PEEK 450P requires processing at higher temperatures (380-400°C) to maintain good flowability, while precise control of mold temperature is necessary to promote rapid cooling and reduce residual stress. In extrusion, the requirements for PEEK 450P`s flowability and cooling rate may differ, focusing more on the material`s continuous flow and uniform cooling to ensure product dimensional stability and uniformity. Different processing techniques impact PEEK 450P`s mechanical properties and surface quality; therefore, optimizing processing conditions is crucial for achieving specific application requirements.

Is PEEK 450P sensitive to ambient humidity? How does it affect its final product performance?

PEEK 450P is relatively sensitive to ambient humidity. Before processing, it is recommended to dry PEEK 450P at 150°C/3 hours or 120°C/5 hours to ensure the residual moisture is less than 0.02%, as moisture will evaporate during processing, possibly leading to bubble formation or physical property degradation . The impact of humidity on PEEK 450P is mainly reflected in the processing process. Proper pre-drying can effectively prevent humidity-related problems and ensure that the final product has excellent mechanical properties and dimensional stability.