- Home

- Companies

- Prayon S.A.

- Products

- Prayon - Model DA-HF - Phosphoric Acid

Prayon - Model DA-HF -Phosphoric Acid

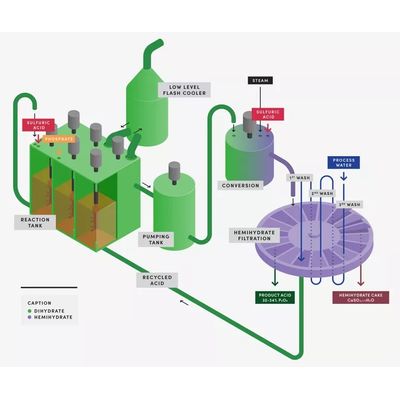

Cutting-edge process to produce phosphoric acid with a high recovery efficiency. The Prayon DA-HF Process is a modern process developed and industrially implemented by Prayon. It is an economic and efficient solution to produce phosphoric acid and valuable gypsum as a co-product. It consists in the attack of the phosphate rock under dihydrate conditions. Then, the gypsum slurry is converted to hemihydrate by the addition of sulfuric acid and steam in a specific circular reactor designed by Prayon. Hemihydrate slurry is filtered on a Prayon tilting pan filter to recover a good-quality calcium sulfate. Depending on the rock processed, the ex-filter acid strength is typically 32-34% P2O5 and the typical P2O5 recovery efficiency is 97%.

When should we select Prayon DA-HF Process?

- Low investment cost

- Especially considering the revamping of an existing Dihydrate plant

- High P2O5 recovery

- Low P2O5 content in the phosphogypsum

- Suitable for cement and building applications

- Self-drying phosphogypsum

- With a final moisture around 10-12%

- Limited grinding of the rock

- Low cadmium in the product acid

When should Prayon DA-HF Process be applied?

- Where medium- to high-cost rock is accessible

- Where energy cost is rather high

- Steam and electricity

- Where gypsum disposal is limited and/or where a potential market for gypsum has been identified

- Cement or building applications

- To increase production capacity by minimum 20%

- With limited changes in an existing Dihydrate plant