- Home

- Companies

- Presona AB

- Products

- Presona - Model LP 50 EHF - Prepress ...

Presona - Model LP 50 EHF -Prepress Technology Baler

The baler: Robust design with highest possible reliability. User and service friendly. Optimized bale size and big feed opening. Friction channel pressure control within a fixed frame. The upper friction flap pressure controlled by means of a hydraulic cylinder, ide friction flaps controlled manually by means of adjusting screws. The friction flap pressure level adjustable from the control panel. Main press top and bottom with cam design for better sealing. Main press rolling on four heavy-duty wheels guided on wear rails mounted in the press bottom. Heavy duty bearings for the pre-press shaft, bearings with exchangeable shaft sleeves. Sturdy wear blocks on side and top. Bottom plate made of 16 mm long-life resistant steel. Exchangable wear rails in the bottom. Support legs (optional) to eliminate the need of a needle pit. Detection system of the pre-press position during operation to secure a safe interlock of inspection hatches and protection covers.

- Ensures that the material always produces a constant counter pressure in the main press chamber.

- Up to 30 % lower energy consumption compared to a baler without prepress.

- No knives on the main ram, no risk for material jamming between knives and press plate.

- All of the press force utilized for material compaction.

- Increased volume capacity of the machine; the number of prepressing operations may be determined depending on the material to be baled.

- Guarantees an even density throughout the bale = square bales.

- Makes it possible to bale big size material without using a shredder.

- Makes it possible to bale most recyclables to dense, square bales.

- Low service and maintenance costs.

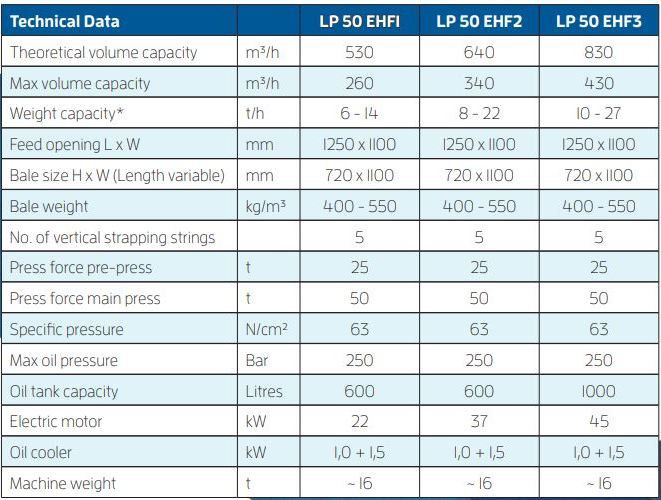

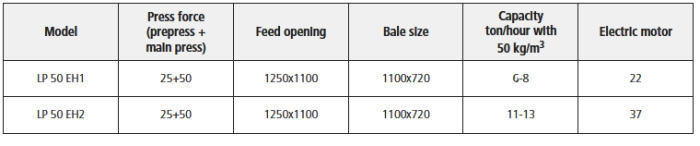

- Main drive motor 22 kW (EH1), 37kW (EH2) and 45 kW (EH3) with a double hydraulic pump system

- Oil level control system

- Oil temperature transmitter - oil temperature indicated on control panel screen

- Oil cooler

- Oil heater (optional)

- All hydraulic components from well reputed, established suppliers.

- Strapping system with fully automatic tying unit for 5 polypropylene strings.

- Automatic knotter and string cutting device.

- The tensile strength of the polypropylene string is comparable to steel wire.

- PREMI 50 HMI Interface system with a fixed Internet connection for operation control and monitoring, presetting of 20 baling programmes.

- Easy operation with a 12” colour Touch Screen

- Quick couplings for quick and safe installation

- A photocell system for baler and conveyor control

* At a material pre-bale density of 30 - 100 Kg/m³

Performance rates and bale densities are subject to moisture, material pre-bale densities, feed rate and other variables

when baling.

As part of our continuous product development, specifications are subject to change without notice.

This baler is available with these options:

- Plastic strapping unit Tying unit for polypropylene wire.

- Waste design Hardened steel plates in the baler’s friction chamber in order to prolong the lifespan of the baler when baling hard-wearing materials like waste and PET.