- Home

- Companies

- Rädlinger primus line GmbH

- Products

- Primus Line Rehab - Pressure Pipes ...

Primus Line Rehab - Pressure Pipes Trenchless Rehabilitation

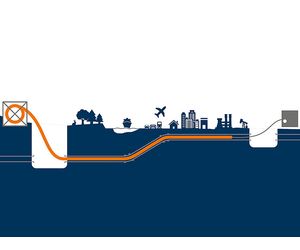

The Primus Line® Rehab system is a proven and environmentally orientated technology for rehabilitating ageing pipelines. It is suitable for transporting various media such as water, gas and oil and is approved for drinking water in Germany, Austria and Switzerland as well as many other countries. The ideal flow characteristics due to a smooth inner coating and the optimised systems for diverse pressure ratings make Primus Line® Rehab a technically and economically optimal solution (depending on the individual case) with a lifetime of more than 50 years. In this way, network operators benefit from reliable operation and a sustainable investment in their pipeline network. Flexible solution for the trenchless rehabilitation of pressure pipelines in the water, gas and oil sectors.

Safety

- Core made of seamlessly woven Kevlar® fabric. This synthetic fibre is up to ten times stronger than steel

- The burst pressure of the flexible pipe is at least 2.5 times the allowable working pressure

- No work with hazardous materials on site

- Continuously monitored production process

Cost advantage

- Installation speeds of up to 10 metres per minute

- Up to 2,500 metres per pull

- Short downtimes thanks to quick recommissioning

- Low pre-investment for installation companies

- Service life of more than 50 years

Efficiency

- Installation through multiple bends up to 90 degrees

- Withstands thermal expansion of the host pipe and ground movement

- Burst pressure rates up to 206 bar

- Operating pressure up to 82 bar

- Independet of host pipe

- No curing, steaming, adhesion or thermal treatment of the liner after installation required

- Almost independent of weather conditions during installation

Environmentally orientated

- Minimum use of machinery: This can result in a significant reduction of the carbon footprint

- Installation via small excavation pits, chambers and structures

- Decreased impact on traffic

- Only small construction site areas required

- Reduction of the on-site carbon footprint by up to 90 per cent compared to dig and lay

- We also pay attention to sustainability as a company

Primus Line® is installed trenchlessly. This means: No more excavation pits with a length of several hundred metres of even several kilometres.

Two pits or existing shafts are sufficient for rehabilitating pressure pipelines. To complete the installation, just a few steps are necessary:

Preparation

- Creating the access

- Decommissioning the pipeline

- Inspecting the host pipe

- Cleaning the host pipe

Installation

- Inserting the liner

- Mounting the connectors

- Pressure test

Reintegrating the rehabilitated pipeline

- Installing a fitting piece

- Comprehensive documentation

Nominal widths

DN 150 to DN 500

Wall thickness

6 and/or 8 millimetres

Installation in bends

up to 90 degrees possible

Maximum operating pressure

up to 82 bar (depending on the diameter)

Temperature resistance

more than 30 degrees Celsius (up to 60 degrees Celsius under certain conditions)

Friction coefficient

k = 0.028 millimetres

Installation length

up to 2,500 metres in one section

Media resistance

suitable for numerous liquid media