- Home

- Companies

- Nederman National Conveyors

- Products

- Pressure Pneumatic Metal Chip Conveying ...

Pressure Pneumatic Metal Chip Conveying System

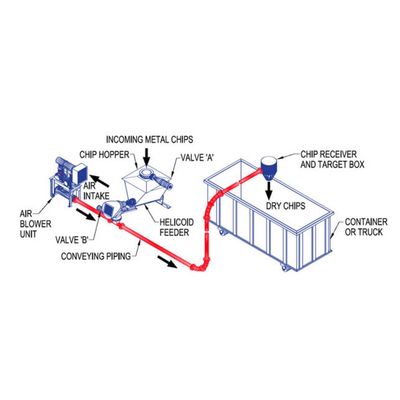

Referring to the diagram shown above, incoming metal chips (from chip wringing operations or other sources) are fed into the system airlock feeder through valve "A" filling the chip storage hopper. Valve "B" is closed. When the hopper is full, valve "A" closes, valve "B" opens, and a helicoid (screw) feeder fitted to the hopper bottom provides a metered stream of chips into the pneumatic conveying pipeline. For short distance conveying, a self relieving, anti-jam rotary airlock feeder can be provided. Metal chips are normally conveyed to a distant chip receiver/target box (located above a roll-off container or truck) where chips are separated from the airflow. Alternatively, chips may be delivered to a storage silo for subsequent loadout. An upstream mechanical blower unit provides the pressurized airflow for conveying of metal chips.