Nederman National Conveyors products

Stand Alone Metal Chip Processing Systems

Pneumatic Chip Wringing System

The National VD40 compact pneumatic chip wringing system is an economical and effective method for drying and conveying metal chips where there is limited floor space. The model VD40 chip wringer can be placed directly under the discharge of a single machine tool conveyor or the VD40 can serve multiple machine tools as shown in the following diagrams and photographs. The pneumatic air flow developed by the chip wringer provides a means for conveying "dry" metal chips for a maximum distance of 30-40 feet (9m-12m) to a container. Guards, Safety Placards and Safety Devices may have been removed for the purpose of clarity

Metal Chips

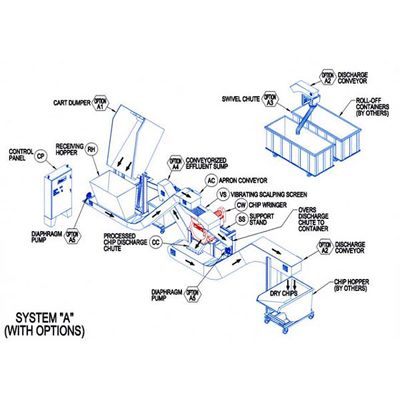

Metal Chips from machining operations are delivered to receiving hopper (RH) from which they are conveyed by a hinged steel belt conveyor (AC) to a vibrating screen (parts separator) (VS) for separation of the occasional tool or part. Chips passing through the screen report by gravity to a horizontal bowl continuous chip wringer (centrifuge) (CW) where residual cutting fluids are extracted and discharged to effluent collection sump (ES). Dry metal chips are discharged via chute (CC) to a container. The entire system is controlled from master control panel (CP) fitted with a programmable logic controller.

Pneumatic Chip Collection Conveying Systems

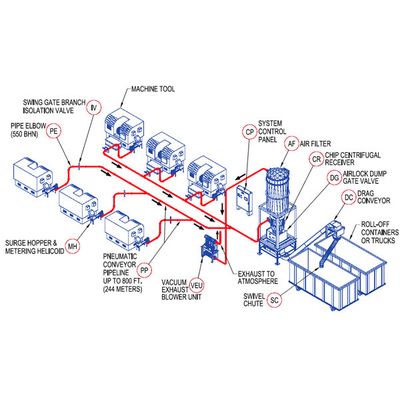

Vacuum Pneumatic Metal Chip Collection & Conveying

Metal chips are sequentially collected from multiple collection points, such as machine tools, by a vacuum pneumatic conveying system which transports them through pipelines to a central receiving station where they are separated from the induced air flow and discharged into a disposal container storage bin or automatic loadout system. The conveying air flow generated by a mechanical exhauster is filtered prior to discharge into the atmosphere.

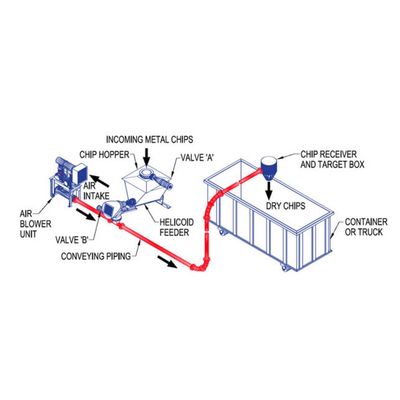

Pressure Pneumatic Metal Chip Conveying System

Referring to the diagram shown above, incoming metal chips (from chip wringing operations or other sources) are fed into the system airlock feeder through valve "A" filling the chip storage hopper. Valve "B" is closed. When the hopper is full, valve "A" closes, valve "B" opens, and a helicoid (screw) feeder fitted to the hopper bottom provides a metered stream of chips into the pneumatic conveying pipeline. For short distance conveying, a self relieving, anti-jam rotary airlock feeder can be provided. Metal chips are normally conveyed to a distant chip receiver/target box (located above a roll-off container or truck) where chips are separated from the airflow. Alternatively, chips may be delivered to a storage silo for subsequent loadout. An upstream mechanical blower unit provides the pressurized airflow for conveying of metal chips.

Ash Handling Systems

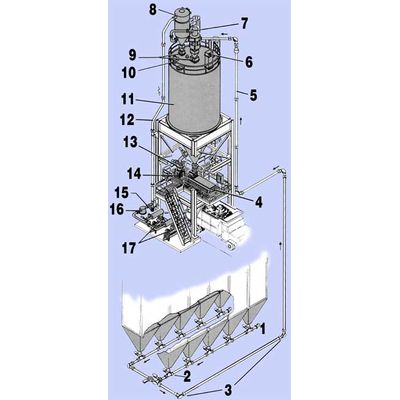

Vacuum Pneumatic Ash System Operation

Ash which has accumulated in various collection hoppers is pneumatically conveyed to a centrifugal receiver atop the ash storage silo. Vacuum forces providing the conveyance air flow are created by a blower (exhauster) located near the silo. Coarser ash particulates collecting at the bottom of the receiver are transferred to the silo via a double dump gate air lock assembly ( see description on following page). Finer ash particles and the induced conveying air flow report through the "vortex finder" pipe at the top of the centrifugal receiver to a pulse jet, bag type dust collector located nearby. Ash particulates released by periodic blow down of the bags collect below, where this material is transferred to the silo via a double dump gate air lock assembly. Overall solids recovery typically exceeds 99.9% for 2 micron and larger particulates.