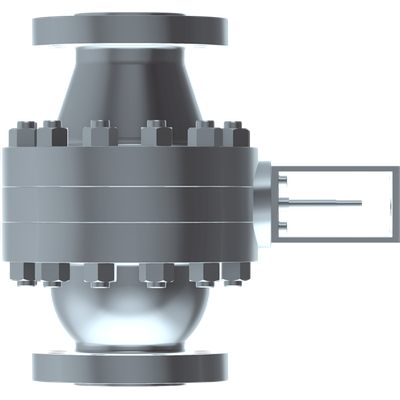

Twister - Model SwirlValve -Pressure Reduction Valve

The Twister SwirlValve improves the separation of two-phase flow across a pressure reduction valve such as a choke valve, JT valve or control valve. Economic benefits include more flow throughput, increased gas handling capacity, a rise in natural gas production, and the reduction in bottlenecks found in existing overloaded separators.

- Increased gas handling capacity

- Increased NGL production (C6+)

- Lower export gas dew points

- Easy to retro-fit in existing piping arrangement

- Debottlenecks existing overloaded separators by creating droplets in the valve

- Less liquid carry-over/gas carry under

Efficiency

Using the free pressure drop available in JT operation, the SwirlValve creates a rotating flow increasing droplet size and hence improving the separation efficiency of downstream separation equipment.

Simplicity

Similar to standard cage type control valves with pressure balanced piston, the SwirlValve design results in a compact valve with a small actuator.

Reliability

Based on a standard cage flow control valve, SwirlValve builds on a well proven concept.

Profitability

Ideal for brownfield applications, replacing a JT valve with a SwirlValve debottlenecks downstream separator trains. Alternatively a reduced pressure drop in JT-LTS processes can be applied while maintaining dewpoint specifications.