- Home

- Companies

- ProMinent GmbH

- Products

- ProMinent - Model Orlita Evolution - ...

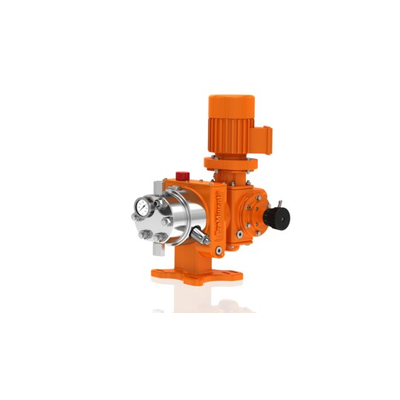

ProMinent - Model Orlita Evolution -Hydraulic Diaphragm Metering Pump

Capacity range of single-head pump: 3 – 7400 l/h, 400 – 10 bar. The ORLITA Evolution meets the most exacting safety requirements as an extremely robust hydraulic diaphragm metering pump. It is characterised by its PTFE multi-layer diaphragm with integral diaphragm rupture warning/signalling and unique diaphragm position control.

Maximum process reliability and flexibility.

The ORLITA Evolution hydraulic diaphragm metering pump range of EF1a, EF2a, EF3a and EF4a form an integrated product range with stroke lengths of 15 to 40 mm. This covers the capacity range of 3 to 7,400 l/h at 400 – 10 bar. A wide range of drive versions is available, including some with ATEX certification for use in Zone 1 or Zone 2 areas at risk from explosion. The ORLITA Evolution product range is designed to comply with API 675.

Maximum process reliability:

- PTFE multi-layer diaphragm with integral diaphragm rupture warning / signalling system

- Integral hydraulic relief valve

- The new diaphragm position control protects against impermissible operating statuses (e.g. no damage in the event of a blockage on the suction or discharge side)

- The dosing precision is better than ± 1 % within the 10-100 % stroke length adjustment range under defined conditions and with correct installation

- Continuous bleeding of the oil chamber ensures reliable operation

Excellent flexibility:

- The modular and compact construction with single and multiple pump versions permits a wide range of applications. In multiple pump systems up to 5 metering units can be combined, including units with different pump capacities

The following list of applications are general examples of generally suitable applications for this product. Please contact your local sales representative to talk about the applicable use of this product in your specific case / environment.

- Oil and gas industry

- Metering of reactants and catalysts in the chemical industry

- Volume-proportional metering of chemicals/additives in the treatment of boiler feed water

- Level-dependent metering of auxiliary agents in industrial production engineering, for instance hot wax metering in the production of adhesive strips

Technical Details

- Stroke length: 0 - 16 mm (Evo 1, Evo 2), 0 - 25 mm (Evo 3), 0 - 40 mm (Evo 4)

Rod force: 2,300 N (Evo 1), 5,400 N (Evo 2), 8,000 N (Evo 3), 15,700 N (Evo 4) - Stroke length adjustment range: 0 – 100 %

- Stroke length adjustment: manually by means of a manual adjustment wheel and scaled display (optionally with electric actuator or control drive)

- Metering reproducibility is better than ± 1% within the 10 – 100 % stroke length range under defined conditions and with correct installation

- PTFE multi-layer diaphragm with electrical diaphragm rupture warning system via a contact

- Integrated hydraulic relief and bleed valve

- Wetted materials:

Stainless steel 1.4404, special designs available on request

plastics PVC, PVDF, special designs available on request - A wide range of power end versions is available: Three-phase AC standard motors also for use in areas at risk from explosion, different flange designs for use of customer-specific motors

- Degree of protection: IP 55

- Design in compliance with API 675 among others