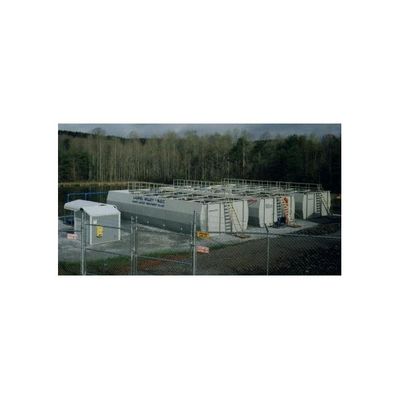

Purestream - Package Sequencing Batch Reactor (SBR)

Purestream's Sequencing Batch Reactors bring STATE-OF-THE-ART, modern technology to a 75 year old proven process for biologically treating wastwater. The SBR system is a natural process of FILL, REACT, SETTLE, DECANT, and IDLE without the use of chemicals. The necessary bacteria, which are found everywhere in nature, can be selectively chosen and cultured in the SBR process to remove carbon, nitrogen and phosphorous found in most wastewater. The simplicity of this time based process makes it easy to control and operate, resulting in an effluent that is low in BOD, TSS, nitrogen, and phosphorous - usually much lower than regulatory requirements. The flexibility of the SBR system allows it to adapt readily to changing conditions of hydraulic and/or organic loads.

Although the Purestream SBR process can be applied successfully to all biologically degradable wastewaters, with minimal operator attention, it is especially suited for the following applications:

Unusually strong and/or variable organic loads created by industrial wastes, such as:

- Meat And Poultry

- Dairies

- Landfill Leachates

Highly variable daily hydraulic flow patterns found in:

- Shopping Centers

- Schools

- Subdivisions

- Campgrounds

- Small Communities

Environmentally sensitive areas requiring advanced treatment, such as:

- Resort Areas

- Commercial Fishing Areas