Purestream, Inc. and Purestream ES , LLC products

Purestream Inc. Products

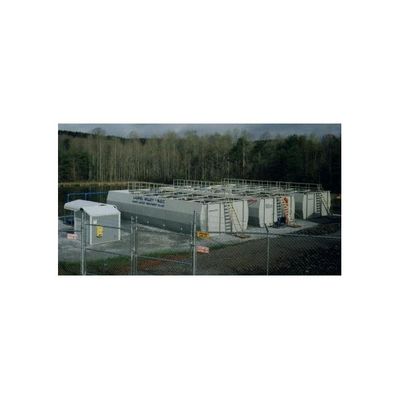

Purestream - Extended Aeration Package Plants

The PURESTREAM, INC. package sewage treatment plant is an Extended Aeration treatment system. This treatment system works by providing ideal conditions for aerobic bacteria and other micro-organisms; these micro-organisms then decompose the biological contaminants in the raw sewage.

Purestream - Low Speed Mechanical Surface Aerators System

The Purestream Sigma low speed surface mechanical aerator is the result of years of development and refinement from hundreds of successful installations. The Sigma aerator offers the user unsurpassed durable construction, flexible design and maximum efficiency for wastewater treatment. These features make the Sigma Aerator the most cost-efficient aerator available.

Purestream - Package Rotating Biological Contactor System

For over 30 years, Purestream, Inc. has been known as a major manufacturer of prefabricated package aeration wastewater treatment systems. This concept has been further developed by utilizing Rotating Biological Contactors to achieve high process efficiency, lower energy consumption, minimal land requirements and low operator attention. In all cases, the components furnished by Purestream, Inc. for the Rotating Biological Contactor Package Plant are completely fabricated in the factory, greatly simplifying installation.

Purestream - Package Sequencing Batch Reactor (SBR)

Purestream's Sequencing Batch Reactors bring STATE-OF-THE-ART, modern technology to a 75 year old proven process for biologically treating wastwater. The SBR system is a natural process of FILL, REACT, SETTLE, DECANT, and IDLE without the use of chemicals. The necessary bacteria, which are found everywhere in nature, can be selectively chosen and cultured in the SBR process to remove carbon, nitrogen and phosphorous found in most wastewater. The simplicity of this time based process makes it easy to control and operate, resulting in an effluent that is low in BOD, TSS, nitrogen, and phosphorous - usually much lower than regulatory requirements. The flexibility of the SBR system allows it to adapt readily to changing conditions of hydraulic and/or organic loads.

Purestream ES Products

Purestream ES - Biologically Engineered Single Sludge Treatment System

The Purestream ES, LLC BESST (Biologically Engineered Single Sludge Treatment) process is a patented (U.S. Patent No. 6,620,322) process that achieves Advanced Wastewater Treatment in a single vessel by incorporating activated sludge processes dating back to the 1920’s. Combining the principals of single sludge treatment for BOD 5, TSS, and Nutrient Removal, as well as sludge blanket clarification into a single vessel, the result is a compact system that achieves a high degree of waste removal. The BESST process has no capacity limits and is used on all sizes and strengths of flows, from smaller housing developments to food processing operations to municipal sectors. For flows from 2,500 gpd to 130,000 gpd Purestream ES, LLC offers the BESST process in a prefabricated steel package or equipment to be installed in a concrete vessel.

Purestream ES - Mechanical Bar Screen

The In-Eko Mechanical Bar Screen is an automated self-cleaning bar screen primarily used for headworks screening of the influent wastewater before entering the treatment plant. It has also been used in freshwater applications to screen the water before entering potable water plants. The supporting structure of the screen is fabricated of non-corrosive 304 stainless steel while the screening belt is formed of an aircraft grade polyamide/fiberglass composite to ensure a long life and peak performance. The screenings brush situated in the head of the screen is made up of durable polyamide fibers to sweep the belt clean. The sprockets and belt guides attached to the drive unit and screening belt are a polyamide nylon that never needs lubrication.

Purestream ES - Microscreen Drum Filter

A part of the mission statement of Purestream ES, LLC is to bring new and innovative advanced wastewater treatment products to the marketplace at a reasonable cost. The In-Eko Microscreen Drum Filter is by far our most convincing proof that we are succeeding. The affordable and user-friendly Microscreen Drum Filter is a compact unit designed to produce high quality tertiary treatment consistently. Available in a stand alone unit or in a configuration to be installed in a concrete channel, the flexibility and low horsepower requirements make this a perfect addition to your new project, or an option to bring existing plants into compliance.

Purestream ES - Robust Screw Screen for Industrial Wastewater Treatment

The In-Eko Screw Screen is the perfect marriage between the Mechanical Bar Screen and a Screw Press. Specifically designed for lower flow applications (less than 1 MGD), the Screw Screen blends the screening capability of the Mechanical Bar Screen with the dewatering and pressing capability of the Screw Press. Available in standard or custom sizes as well as a wide variety of screen opening sizes, the Screw Screen is a great solution for headworks screening on smaller plants.

Purestream ES - Screw Press

| The In-Eko Screw Press is manufactured of 304 Stainless Steel and is a beneficial accessory to the Mechanical Bar Screen. Generally placed below the outfall of the head of the bar screen, the screw press will dewater and compact the screened material. The pressed screenings then travel out the chute into the receptacle of your choice, and the smaller volume of waste results in longer storage capability before having to remove the waste. The water pressed out returns to the channel to go to downstream processes. |

Purestream ES - Sand Separator

The In-Eko Sand Separator is a piece of headworks equipment used to remove sand, glass, small rocks, egg shells, etc. that would normally enter the system. The problem with these items entering the system is that they can possibly damage pumps and other submerged equipment as well as having no organic value.