PURitech Gmbh

- Home

- Companies

- PURitech Gmbh

- Products

- PURItech - Model DPF1/DPF2 - ...

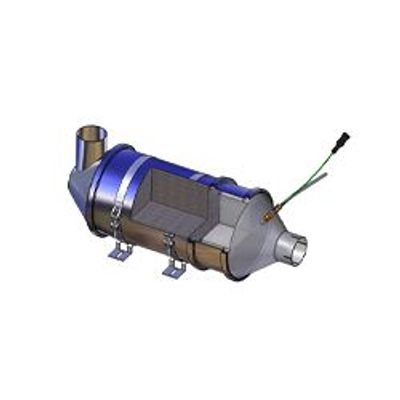

PURItech - Model DPF1/DPF2 -Self-Cleaning System without Downtime with Passive Regeneration

FromPURitech Gmbh

The filter self-cleaning is achieved by a catalytic coated filter surface. The DPF2 system is equipped with an additional pre-filter. That’s why even at low temperatures a self-cleaning regeneration is secured. The DPF1/DPF2 system is designed for construction machines, tractors and stationary engines.

Most popular related searches

self-cleaning filter

soot particle

filter cleaning system

diesel particulate filter

filter cleaning

data logger

particulate filter

temperature sensor

exhaust gas filter

particle filter

- Permanent self-cleaning from 225 C (Average)

- 24 hours operating cycle without downtime

- Monitoring system and system check

- Installation kit available for all common machines

- Self-cleaning filter system without downtime, ideal system for continuous use / multi-shift operation

- Two system versions are available, DPF1 (w/o pre-filter) and DPF2 (with pre-filter)

- Because of the catalytic coating, the system works as a “Combifilter”, particulate filter and catalyst at the same time

- Filter system for machines and vehicles with continuously load / medium exhaust gas temperature

- Permanent, passive filter regeneration through catalytic coating

- VERT approved system with high particle filter efficiency >99%, patented filter technology

- Easy installation as a replacement of the muffler

- Installation kits available for all common machines

- Electronically monitoring and data storage with data-logger

- Application : Medium load / medium exhaust gas temperature

- Type of Regeneration : Passive regeneration

- Regeneration Temperature : DPF1: 250 C (Average), DPF2: 225 C (Average)

- Regeneration Time : Permanent self-cleaning during operation

- Emission Reduction :

- Particle: -99%

- Carbon oxide (CO) -95%

- Hydro Carbons (HC) -99%

- Filter Medium : Filter monolith, Aluminum Oxide (Corderit)

- Approvals : TRGS-554/ TUEV / KBA / AUVA / VERT / CARB et al.

- Warranty : 1 Year

- Maintenance : Filter monitoring: 500 hours / filter cleaning 1000 hours

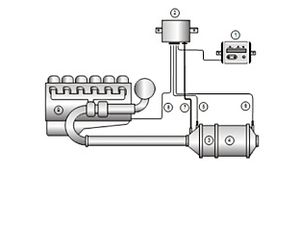

- System monitoring – display

- Monitoring unit / data-logger

- Pre-filter (only DPF-2)

- Diesel particulate filter

- Temperature sensor 1

- Temperature sensor 2

- Backpressure line

- RPM signal

- Diesel engine

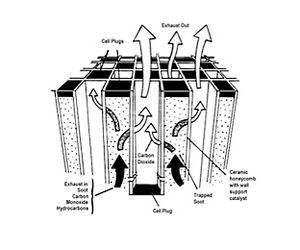

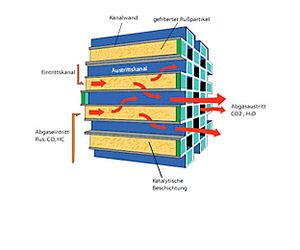

- Monolithic filter block made of Aluminum Oxide

- Honeycomb with reciprocally closed channels

- Channel wall with porous structure

- Exhaust gas flows through channel wall and gets filtered

- Surface of the channels are catalyzed

- Exhaust gas flows into the channels of the filter monolith; each channel is closed at the end of the channel

- The exhaust gas flows through porous channel walls into the output channels and exits the filter as cleaned exhaust gas

- Soot particles are filtered within the high efficient porous channel walls

- A catalytic coating on the channel wall oxidizes the soot particles and converts toxic into harmless substances

- Soot particles are oxidized into water (H2O) and carbon dioxide (CO2), also, carbon oxide (CO) and hydrocarbon (HC) are converted into H2O and CO2. Soot oxidation and emissions are converted already at an exhaust gas temperature of 250C

- Filter monolith is made of high durable aluminum oxide

Engines and vehicles with medium load and medium exhaust gas temperature

- Constructions vehicles

- Tractors

- Stationary engines

DPF1: 250 C average

DPF2: 225 C average