- Home

- Companies

- PURitech Gmbh

- Products

- PURItech - Model DPFN+NC - Diesel ...

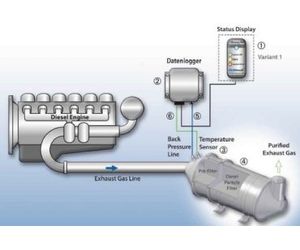

PURItech - Model DPFN+NC -Diesel Particle Filter System

The DPFN+NC system is a self-cleaning wall-flow filter system utilising our exclusively developed passive regeneration technology. The `self-regeneration` occurs through a patented catalytic coating of the pre-filter allowing us to take full benefit of a non-coated wall flow filter monolith. This innovation ensures the lowest cost filter maintenance and replacement service in the UK today( see below). The filter system is suitable for many road vehicle types operating on high/medium duty cycles (exhaust gas temperatures). Typical applications for the DPFN+NC filter system are Touring Coaches and Road Haulage trucks. The filter system`s performance is continuously monitored by on-board data-logging and diagnostic controllers, ensuring regular and valuable feedback to driver and fleet maintenance departments.

The closed passive self-cleaning system provides continuous filter regeneration during vehicle operation. Owing to it`s catalytic coating, the DPFN+NC technology acts as a combined filter system, collecting harmful particulates whilst acting as a catalytic converter simultaneously. The DPFN+NC system is equipped with an additional "Oxicat" increasing the exhaust gas temperature upstream of the filter.

This temperature rise leads to a better soot combustion (regeneration). All our filter technologies are packaged as a `standard version" or as a vehicle specific design for direct `swap` fit. The filter is designed for a 24-hour continuous/ multi-shift operation and has a "life expectancy" of up to 14.000 operation hours with regular maintenance. Filter maintenance savings based on utilisation of tailored PURIclean maintenance programmes. Please enquire further information.

If the vehicle is operated at sufficient load (250-350°C), the filter system regenerates solely passively (catalytic filter coating). The injection of fuel is not necessary at that point. The filter will be charged with soot particles at lower load operation and the backpressure increases. At a specific backpressure level (e.g. 80mbars/free-adjustable), the ECU automatically activates the fuel injection and starts the filter regeneration. The pre-filter oxidizes the injected fuel catalytically and this reaction heat raises the exhaust gas temperature up to 500°C.

- Applicable for : Heavy/Medium duty cycle / exhaust gas temperatures typical of Motorway/A Road

- Regeneration Type : Passive Regeneration

- Regeneration Temp : DPFN+NC: 260°C >60% and 350°>10% of operation time

- Regeneration Time : Continuously self-cleaning during operation

- Emission Reduction : Particle mass -95% / (CO) -95%/ Nanoparticles -99,9% / Hydrocarbons (HC) -99%

- Filter Medium : Cordierite Monolith - Silicon Carbide also available to suit some applications

- Installation : Filter installation in place of, or in addition to existing exhaust silencer

- Passively regenerating system -No fuel additives required

- extended filter maintenance intervalls resulting in lowest maintenance costs

- no increase on fuel consumption

- Professional and speedy installation -usually from start to finish in 1 day

- Monitoring display - LCD

- Monitoring control unit / datalogger

- Pre-filter (oxidation catalyst)

- Diesel particle filter

- Temperature sensor

- Backpressure measuring line