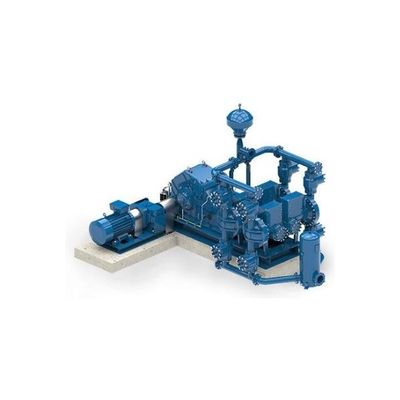

ABEL - Model HMQ -Quadruple-Acting Piston Diaphragm Pump

The Pump for high Flow Rates: The ABEL HMQ has 4 preformed diaphragms and thus is designed for higher performance ranges than the HMD and HMT. The HMQ come to the fore when large volumes (up to 410 m3/h - 1805 GPM) of abrasive materials need to be transferred under high-pressure (up to 25 MPa -3625 psi) conditions. This applies in particular to slurries with a high mineral content, such as in mining.

From tailings management and mine dewatering to backfilling, the ABEL HMQ is used successfully in mining. Mines around the world rely on an ABEL piston diaphragm pump in their production process because of its reliability and safety against failures. In combination with the ABEL Smart Pump Assistant, operators can even increase reliability and safety, as the monitoring system makes predictions and thus acts preventively. Failures can be reduced to a minimum with the SPA and maintenance becomes more plannable.

Especially when compared to single or multi-stage centrifugal pumps to pump tailings and fly ash, pumps from the HMQ series are an interesting alternative in the lower pressure range.

The initially higher investment costs of an ABEL HMQ piston diaphragm pump compared to other pump systems, soon redeem themselves in a relatively short time. The main reasons for this amortization are the reduced energy costs, increased operating time and lower maintenance costs based on experience. Since piston diaphragm pumps easily handle mixtures with high solids concentrations, the amount of water in the medium can also be reduced significantly in some cases.

Piston diaphragm pumps are the first choice worldwide for process-critical pump applications because they can meet the requirements for high availability and process reliability.

Our concept of diaphragm monitoring, which provides a high service life, is the main reasons for the reliability and durability of this pump series. The ABEL HM is therefore particularly advantageous when working with very difficult media. In conjunction with our decades of design experience, we are able to set new standards for pumping technology and equipment, that are regarded as the market leader by many industries around the world.

- Low operating and maintenance costs due to high overall efficiency, low energy costs and simple maintenance with few wearing parts

- Pre-formed diaphragm: low wear and high process reliability

- Diaphragm control and monitoring increases safety and operation free of faults

- Reliable valve technology with ball or cone valves: problem-free conveyance of sludge with high sand and mineral content, free of blockages when pumping fibrous solids

- Nodular cast iron

- Stainless steel

- Rubber lined

- Polypropylene

- Ball Valve

- Cone Valve

- Reverse Valve

- Tailings/Sludge/Fluid Transfer

- Filter Press Feed

- Autoclave Feed

- Rotary Kiln Feed

- Gland Seal Water

- Spray Dryer Feed

- Mine Dewatering

- Mine Backfilling