- Home

- Companies

- Rapid Granulator AB

- Products

- Rapid - Model 200 Series - Granulators

Rapid - Model 200 Series -Granulators

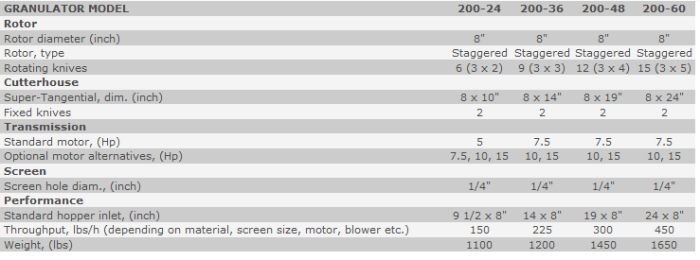

The new Rapid 200 Series is ideal for direct recycling of plastic waste and rejects primarily from injection molding and blow molding processes. No matter what your requirements, a standard model is available to suit your exact needs for capacities up to 450 lbs/h. The number of standard alternatives, like cutterhouse width, rotor configuration, rotor speed, discharge systems, etc., allow you to select the granulator best suited to your type of plastic waste, throughput volume, granule size and direct recycling requirements.

- Beside the press granulator

- Low energy consumption

- Highest regrind quality

- Compact and versatile

- Increased granulation capacity

Cassette knife system. Quick and easy knife changing thanks to the system with cassette knives that do not require any presetting. Just put in position and tighten.

High granulation capacity. The tangential feed of the cutterhouse reduces flyback of waste and enables firm feed

ing of lightweight material to increase grinding capacity.

Low energy consumption. The configuration of the rotor blades and low rotation speed combine to minimize energy consumption.

Constant Cutting Circle, CCC. Guarantees the correct distance between screen and knives, that is one of the cruicial factors for high quality regrind, after multiple knife resharpenings.

Compact and mobile. The small granulator foot-print saves valuable floor-space and castors allow units to be moved easily to other locations as required.

Open 3-blade rotor. In certain applications, for example grinding containers, the 3-blade open rotor gets optimal grip and deliver high capacity output.

3rd fixed knife. An additional fixed knife can be used to increase output.

PowerTech package. Wear resistant execution for longer lifetime of wear parts. Useful in particular when recycling abrasive materials.

Infeed hoppers for all types of production. Dedicated designs for feeding with belt conveyor, continous roll feeding of edge trims, film and skeletal waste, feeding of sheets, pipe/profiles. We provide a design that match your type of production.

Level indicator. To protect against build up of material in bin, and possible over heating of granulator, a level indicator is useful. Can be set to different levels of functionality, from basic warning signal to controling of the complete production cell.

Sound proofing. Our granulators can be equipped with integrated sound proofing, if required, to lower the noise that is generated by all granulators. In situations when extra low levels are desired the new modular Rapid MSS is ideal, building a flexible sound cabinet around the source of noise.

Hour counter. Useful to keep record of service intervals etc.