- Home

- Companies

- Rapid Granulator AB

- Products

- Rapid - Model 400 Series - Medium Size ...

Rapid - Model 400 Series -Medium Size Granulators

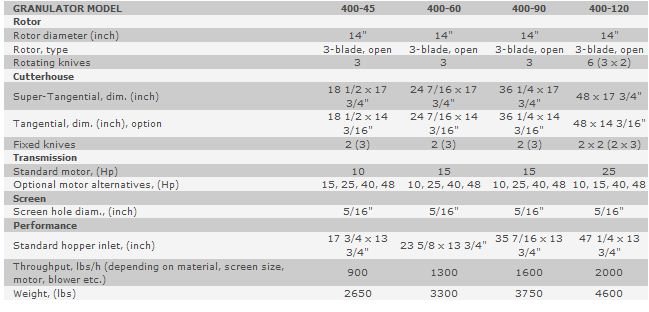

The new 400 Series medium-size granulators are used for central or beside-the-press operation with all kinds of molding processes. Typical waste includes sprues, runners, molded items, profiles, smaller pipes and sheets. The Rapid 400-series comes in 4 widths, 18", 24", 36" and 48". The big benefit with Rapid’s “open-hearted” engineering concept is that it provides direct and easy access to the heart of the machine and gives very rapid cleaning and maintenance times for fast production changeovers. The clear access to core machine parts also allows “visibly clean” inspection and approval, preventing contamination at color and material changes.

- Open-Hearted design!

- “Visibly clean” inspection

- Maximize uptime

- Highest quality regrind

- Extremely short pit stops

- No compromises

"Open-Hearted" design. Provides full and easy access to the complete cutterhouse interior, including the granule bin and screen. When servicing, this gives unmatched access to both rotating and fixed knives. And, you get complete control of the cleaning when changing material and/or color – Visibly clean inspection.

"Super-Tangential" cutter house design. The Super-Tangential cutterhouse is ideal for voluminous parts and scrap providing excellent grip. Available with two fixed knives.

Double scissors cutting action. Provides efficient cutting of the plastics and save energy.

Constant Cutting Circle, CCC. Guarantees the correct distance between screen and knives, that is one of the cruicial factors for high quality regrind, after multiple knife resharpenings.

Pre-adjustable knives. Minimize downtime when changing knives and enables exact setting of the knife gap, crucial to get high quality regrind.

Swing out cutter house front/cradle. Gives full access to cutter house interior. Cleaning and maintenance with complete visibility and accessability.

Heavy duty transmission. Provides powerful and at the same time energy saving granulation. Can be extended with optional increased inertia and friction clutch.

- Infeed hoppers for all types of production. Dedicated designs for feeding with belt conveyor, continous roll feeding of edge trims, film and skeletal waste, feeding of sheets, pipe/profiles. We provide a design that match your type of production.

- Cutter house design "Tangential". For more thick-walled and compact parts the Tangential cutter house is ideal. Configuration includes two fixed knives, if increased throughput is required, a third fixed knife can be specified. The 5-blade rotor to further increase throughput is also an option.

- Additional fixed knives can be specified depending on cutterhouse configuration. Two are standard in all. Up to two extra can be specified related to cutterhouse design.

- Second flywheel. The extra flywheel gives extra power in applications where greater power is needed in the cutting moment.

- Knife setting jig. To minimize downtime and to achieve the exact knife gap, required for high quality regrind production, the knife setting jig is a useful tool.

- PowerTech package. Wear resistant execution for longer lifetime of wear parts.

- Sound proofing. Our granulators can be equipped with integrated sound proofing, if required, to lower the noise that is generated by all granulators. In situations when extra low levels are desired the new modular Rapid MSS is ideal, building a flexible sound cabinet around the source of noise.

- Level indicator. To protect against build up of material in bin, and possible over heating of granulator, a level indicator is useful. Can be set to different levels of functionality, from basic warning signal to controling of the complete production cell.

- Electrical jack opening. The electrical jack simplifies opening and closing of the hopper.