- Home

- Companies

- Rapid Granulator AB

- Products

- Rapid Raptor - Shredder

Rapid Raptor - Shredder

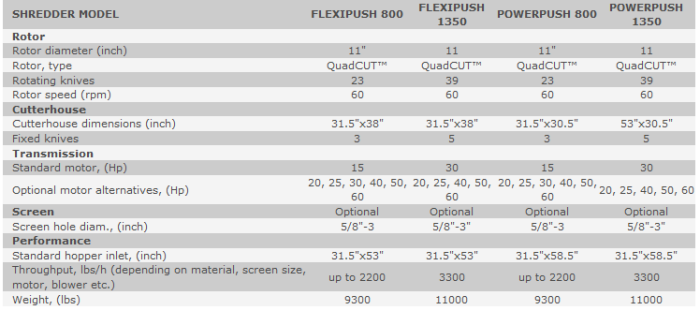

The Rapid RAPTOR shredders are unique in many ways. They are designed for all types of plastics, large 1200 lit IBC containers or heavy lumps, all are efficiently recycled. The new patented Rapid QuadCUT™ knife design offers four true cutting edges per knife in a solid piece which makes the knives the toughest you can get. The knives are clamped in a rock solid design, including a shock absorber to protect the rotor from being destroyed in a sudden impact from any metal etc. that accidentally have entered the cutter house. The shredders come in two widths, 800 and 1350 mm. The standard version comes with FlexiPUSH (pneumatic pusher). For voluminous light weight goods, a TopPUSH (pneumatic) can be added. In case extra power is needed the PowerPUSH version (hydraulic pusher) is recommended.

- Recycle all plastic

!

- Open-Hearted technology

- New rotor design – impact protection

- QuadCUT™ – Patented unique knife design

- Customizeable tilt back hopper

- QuadCUT Rapid’s new patented cutting system. A complete new knife design combining a rock solid clamping design with four long-lasting knife edges. Each knife has a built-in shock absorber which helps to protect the rotor from sudden impacts.

- Single unit fixed knife system. The unique fixed knives solution is based on a single article which fit in all positions and all widths. The turnable knives have 4 true cutting edges. Knife position is pre-set and knife clearance can easily be fine tuned.

- Heavy duty transmission. The heavy duty design of the gear box makes it reliable, energy efficient and at the same time quiet. It’s belt driven for efficient operation.

- PLC programming. The Raptors come with programs for standard applications. More flexibility is achieved by optional PLC programming, also offering operation and logging from a ipad or PC.

- Extensive safety systems. With multiple sensors, the Raptors are safe to operate. Access is not given until the rotor has stopped.

- Split cutterhouse. If a worst case scenario should happen and the rotor needs to be removed for repair it is easily done. The split cutterhouse sides make the rotor easy to lift out of the machine without removing the hopper.

- Double knife rows. In certain applications, a rotor with double knife rows can be used to increase the capacity.

- Advanced PLC programming. Extended PLC capabilities to run different programs

- TopPUSH. A top pusher, pressing bulky light weight materials down to the rotor, increase throughput in certain applications.

- Infeed alternatives. A belt conveyor or a pallet turner makes infeed more convenient.

- Screens. The Rapid RAPTOR operates screenless. However, if a more homogeneous output is required, screens from 16-75 mm hole diameter can be used. No welding required, just open door and insert the screen (for Raptor 1350 screens are split in two for easier hanling).

- Mineral Composite Technology Base, MCT. The Raptor-Series’ base can be made of a special mineral composite material to give extra stability, reducing vibrations even in the toughest applications.